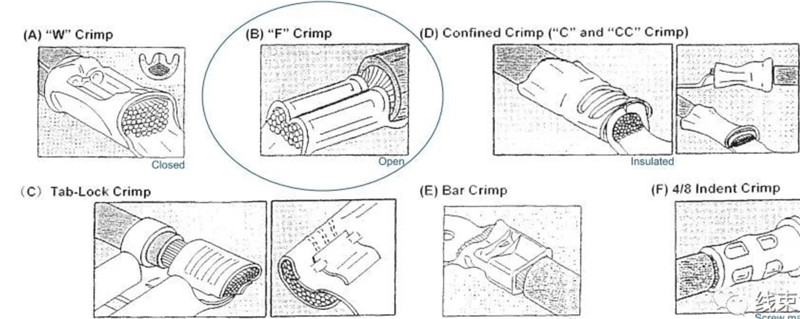

1. Yini i-crimping?

I-Crimping inqubo yokufaka ingcindezi endaweni yokuxhumana yocingo kanye netheminali ukuze iyenze futhi ifinyelele ukuxhumana okuqinile.

2. Izidingo ze-crimping

Ihlinzeka ngoxhumano olungenakuhlukaniswa, lwesikhathi eside oluthembekile lukagesi kanye nemishini phakathi kwamatheminali e-crimp namakhondakta.

I-crimping kufanele ibe lula ukwenza nokucubungula.

3. Izinzuzo ze-crimping:

1. Isakhiwo se-crimping esilungele ububanzi bocingo oluthile nogqinsi lwempahla lungatholwa ngokubala.

2. Ingasetshenziselwa ukugoqa ngamadayamitha ocingo ahlukene kuphela ngokulungisa ukuphakama kwe-crimping

3. Izindleko eziphansi ezizuzwe ngokukhiqizwa kokugxiviza okuqhubekayo

4. I-Crimping automation

5. Ukusebenza okuzinzile ezindaweni ezinokhahlo

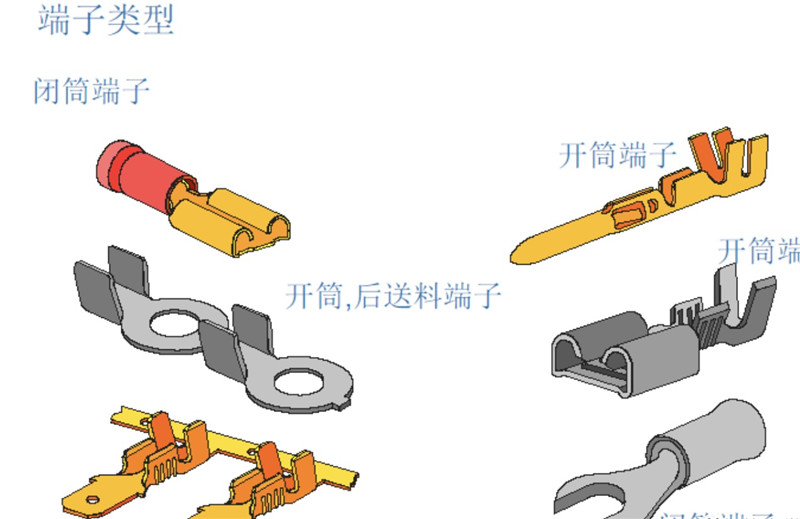

4. Izakhi ezintathu ze-crimping

Intambo:

1. Ububanzi bocingo obukhethiwe buhlangabezana nezidingo zokusebenziseka kwetheminali ye-crimp

2. Ukukhumula kuhlangabezana nezidingo (ubude bufanelekile, ukumbozwa akonakali, futhi ukuphela akuqhekeki futhi kuhlanganiswe kabili)

2. Itheminali

Ukulungiswa Kwe-Crimp: Ukukhethwa Kwetheminali

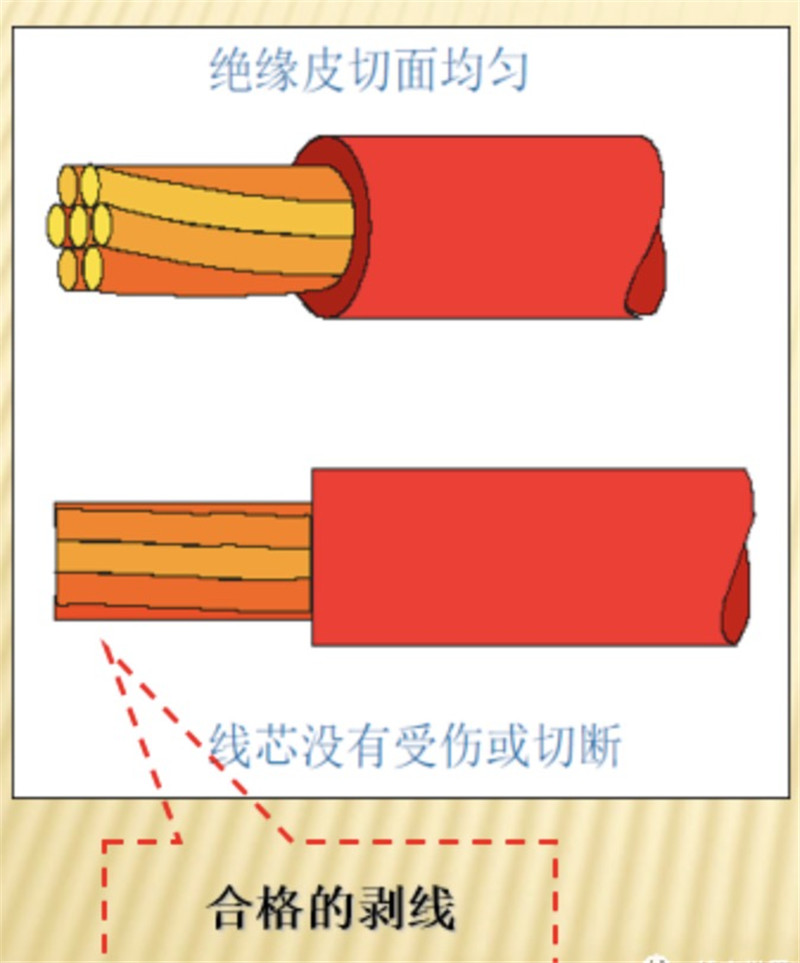

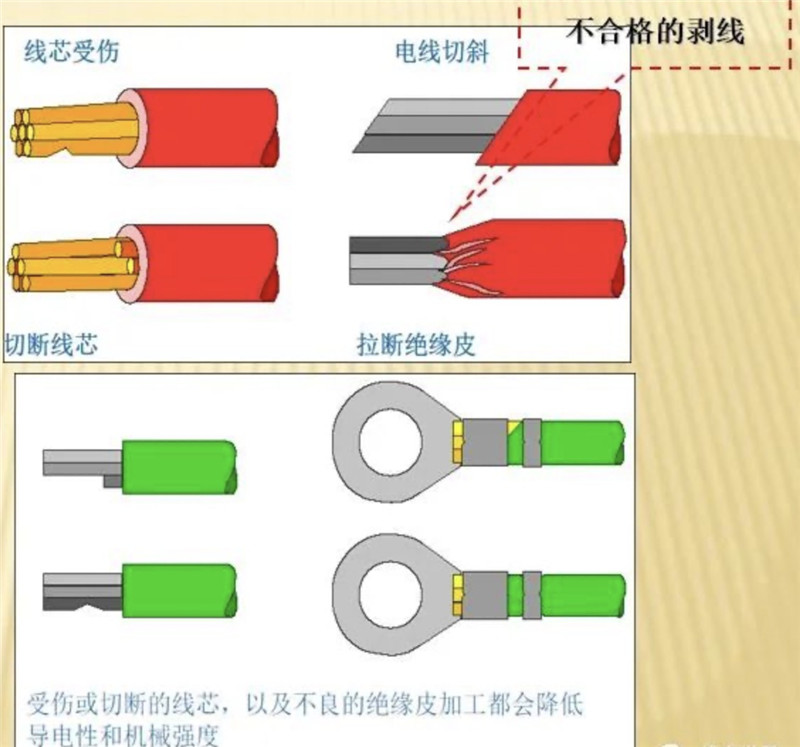

Ukulungiselela I-Crimp: Izidingo Zokuhlubula

Ukukhumula izintambo kufanele kunake lezi zidingo ezijwayelekile ezilandelayo

1. Ama-conductors (0.5mm2 nangaphansi, kanye nenani lezintambo lingaphansi noma lilingana nama-cores angu-7), angeke alimale noma asikwe;

2. Amakhondatha (0.5mm2 kuya ku-6.0mm2, futhi inani lezintambo likhulu kunezintambo ezingu-7), izintambo eziyinhloko zonakalisiwe noma inani lezintambo ezisikiwe alikho ngaphezu kuka-6.25%;

3. Ngezintambo (ngaphezulu kuka-6mm2), intambo eyinhloko yonakele noma inani lezintambo ezisikiwe alikho ngaphezu kuka-10%;

4. I-insulation yendawo engakhumuli ayivunyelwe ukuba yonakaliswe

5. Akukho ukwahlukanisa okuyinsalela okuvunyelwe endaweni ehlutshiwe.

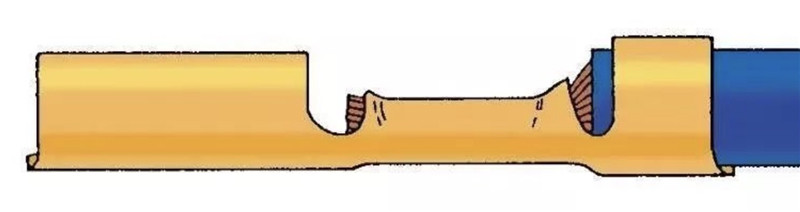

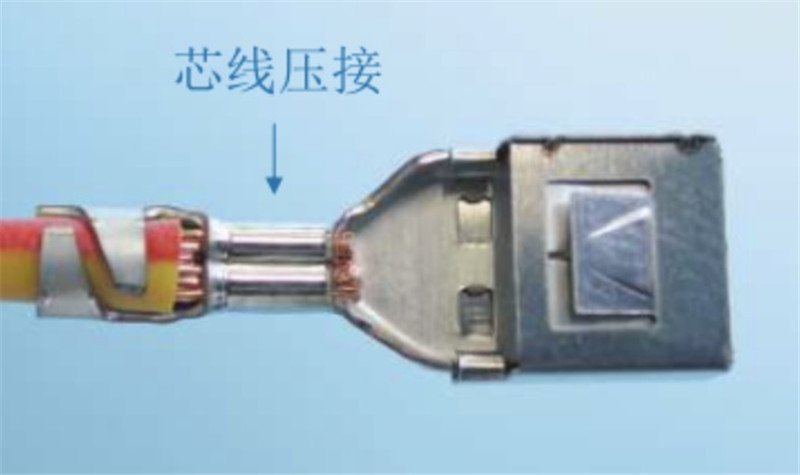

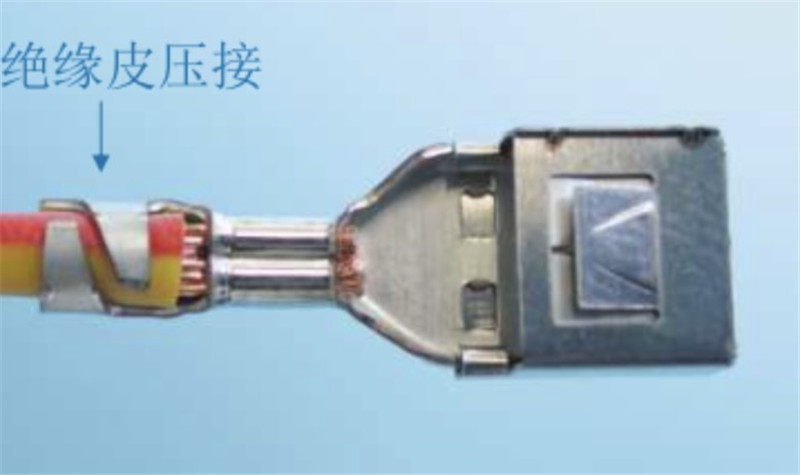

5. I-core crimping kanye ne-insulation crimping

1. Kunomehluko othile phakathi kwe-core crimping kanye ne-insulation crimping:

2. I-core crimping iqinisekisa ukuxhumana okuhle phakathi kwetheminali nocingo

3. I-insulation crimping iwukunciphisa umthelela wokudlidliza nokunyakaza ku-core wire crimping.

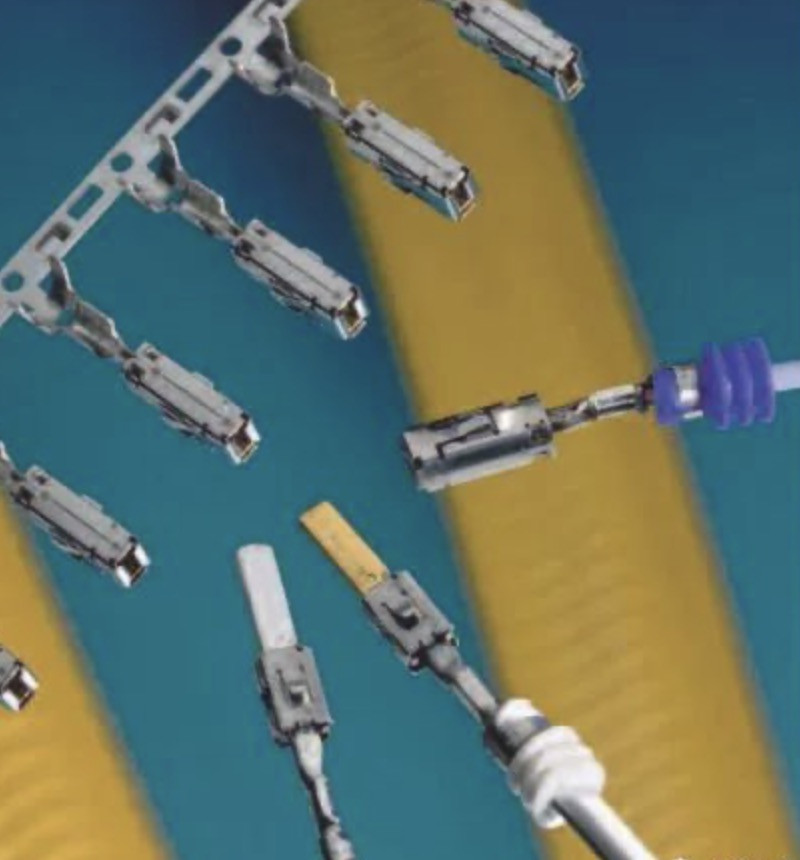

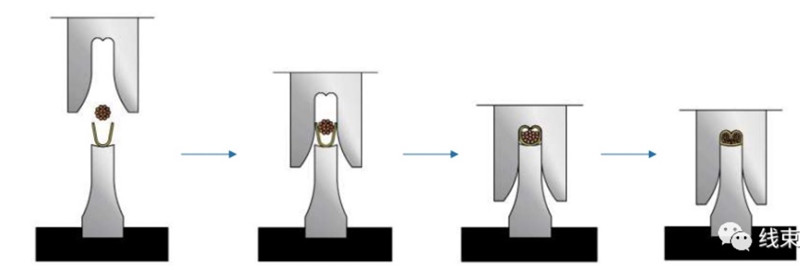

6. Inqubo ye-Crimping

1. Ithuluzi lokukhiya liyavulwa, i-terminal ibekwe phezu kommese ongezansi, futhi ucingo lufakwa endaweni ngesandla noma ngemishini.

2. Ummese ongaphezulu uya phansi ukuze ucindezele ucingo emgqonyeni

3. Ishubhu yephakheji igotshwe ngommese ongenhla, futhi i-crimped futhi yakhiwe

4. Ubude be-crimping obumisiwe buqinisekisa ikhwalithi ye-crimping

Isikhathi sokuthumela: Jul-04-2023