Ngokuthuthuka okusheshayo kwemishini kagesi, izimoto nobunye ubuchwepheshe be-elekthronikhi, isidingo semakethe samahhanisi ezintambo siyaqhubeka nokukhula. Ngesikhathi esifanayo, iphinde ibeke izidingo eziphakeme emisebenzini nasezingeni elifana ne-miniaturization ne-lightweight.

Okulandelayo kuzokwethula ezintweni ezidingekayo zokuhlola ukubukeka ukuze uqinisekise ikhwalithi yamahhanisi ezintambo. Futhi yethula izimo zohlelo lokusebenzisa uhlelo olusha lwesibonakhulu sedijithali ye-4K ukuze kuzuzwe ukubhekwa okukhulisiwe, ukulinganisa, ukutholwa, ukuhlolwa komthamo kanye nokwenza ngcono ukusebenza kahle komsebenzi.

Amahhanisi ezintambo ukubaluleka kwawo nezimfuneko ezikhulayo kanyekanye

Intambo yokubopha, eyaziwa nangokuthi intambo yokubopha, iyingxenye eyakhiwe ngokuhlanganisa ukuxhuma okuningi kukagesi (ukunikezwa kwamandla, ukuxhumana kwesignali) izintambo ezidingekayo ukuze kuxhunywe okokusebenza kwe-elekthronikhi kunqwaba. Ukusebenzisa izixhumi ezihlanganisa abathintwayo abaningi kungenza uxhumo lube lula kuyilapho kuvimbele ukungaxhumeki kahle. Uma sithatha izimoto njengesibonelo, kusetshenziswa amahhanisi ezintambo angu-500 kuya kwangu-1 500 emotweni, futhi lawa mahhanisi angadlala indima efanayo nemithambo yegazi nezinzwa zomuntu. Amahhanisi ezintambo anesici futhi alimele azoba nomthelela omkhulu kwikhwalithi, ukusebenza nokuphepha komkhiqizo.

Eminyakeni yamuva, imikhiqizo kagesi kanye nemishini kagesi ibonise umkhuba we-miniaturization kanye nokuminyana okuphezulu. Emkhakheni wezimoto, ubuchwepheshe obufana ne-EV (izimoto zikagesi), i-HEV (izimoto ezixubile), imisebenzi yokusiza ukushayela esekelwe kubuchwepheshe bokungeniswa, kanye nokushayela okuzimele nakho kukhula ngokushesha. Ngokumelene nalesi sizinda, isidingo semakethe samahhanisi ezintambo siyaqhubeka nokukhula. Mayelana nocwaningo lomkhiqizo, ukuthuthukiswa kanye nokukhiqiza, siphinde sangena ekuphishekeleni ukuhlukahluka, ukwenza okuncane, okungasindi, ukusebenza okuphezulu, ukuqina okuphezulu, njll., silwela ukuhlangabezana nenkathi entsha yezidingo ezihlukahlukene. Ukuze kuhlangatshezwane nalezi zidingo futhi kuhlinzekwe ngokushesha ngemikhiqizo emisha nethuthukisiwe yekhwalithi ephezulu, ukuhlolwa ngesikhathi socwaningo nokuthuthukiswa kanye nokuhlolwa kokubukeka phakathi nenqubo yokukhiqiza kufanele kuhlangabezane nezidingo zokunemba okuphezulu kanye nesivinini.

Ukhiye wekhwalithi, uxhumo lwetheminali yezintambo nokuhlolwa kokubukeka

Enqubweni yokukhiqiza amahhanisi ocingo, ngaphambi kokuhlanganisa izixhumi, amashubhu ocingo, abavikeli, izinsimbi zocingo, izinsimbi eziqinisayo nezinye izakhi, inqubo ebalulekile enquma ikhwalithi yezintambo zocingo idinga ukwenziwa, okungukuthi, ukuxhumana kwe-terminal kwezintambo. Lapho uxhuma ama-terminals, "crimping (caulking)", "pressure welding" kanye "welding" izinqubo zisetshenziswa. Uma usebenzisa izindlela zokuxhuma ezihlukene, uma uxhumano lungajwayelekile, kungase kuholele emaphutheni afana nokungahambi kahle kahle kanye nokuwa kwentambo ewumgogodla.

Ziningi izindlela zokubona ikhwalithi yamahhanisi ezintambo, njengokusebenzisa “i-wire harness checker (i-continuity detector)” ukuze uhlole ukuthi akukho yini ukunqanyulwa kukagesi, amasekhethi amafushane nezinye izinkinga.

Kodwa-ke, ukuze kutholwe isimo esithile kanye nezimbangela ngemva kokuhlolwa okuhlukahlukene nalapho ukwehluleka kwenzeka, kuyadingeka ukusebenzisa umsebenzi wokubheka wokukhuliswa kwesibonakhulu kanye nesistimu ye-microscopic ukuze wenze ukuhlola okubonakalayo nokuhlola ingxenye yokuxhumana kwetheminali. Izinto zokuhlola ukubukeka zezindlela ezahlukene zokuxhuma zimi kanje.

Izinto zokuhlola ukubukeka kwe-crimping (i-caulking)

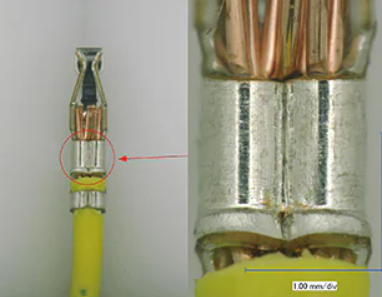

Ngokusebenzisa i-plasticity yabaqhubi be-copper-clad yama-terminals ahlukahlukene, izintambo nama-sheaths anqanyuliwe. Ukusebenzisa amathuluzi noma okokusebenza okuzenzakalelayo emgqeni wokukhiqiza, abaqhubi bezingubo zethusi bayagoba futhi baxhunywe "nge-caulking."

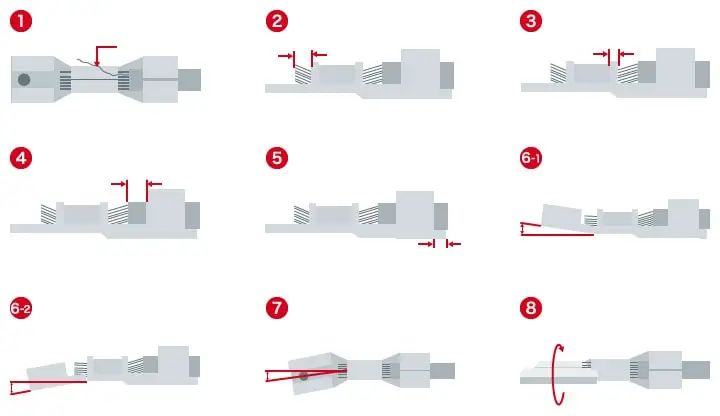

[Izinto zokuhlola ukubukeka]

(1) Izintambo eziwumgogodla ziyaphumela ngaphandle

(2) Intambo ewumgogodla ubude obude

(3) Inani lomlomo wensimbi

(4)Ubude obuphuma emgodleni

(5) Ukusika ubude

(6)-1 igobela phezulu/(6)-2 igobela phansi

(7)Ukuzungeza

(8)Ukuqhaqhazela

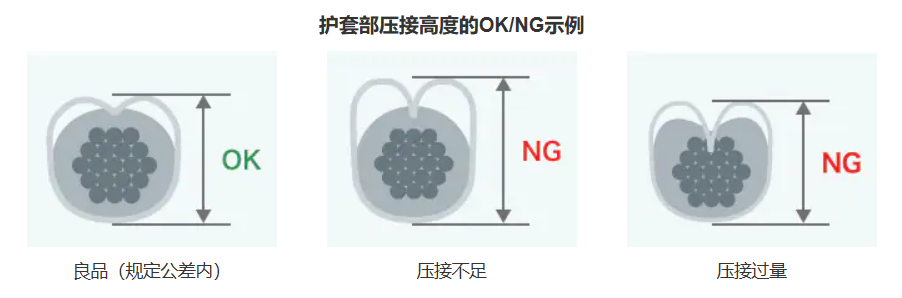

Amathiphu: Umbandela wokwahlulela ikhwalithi yokucwila yamatheminali acijile "ubude be-crimping"

Ngemuva kokuthi i-terminal crimping (i-caulking) isiqediwe, ukuphakama kwesigaba somqhubi we-copper-clad endaweni ye-crimping yekhebula kanye ne-sheath "ukuphakama kwe-crimping". Ukwehluleka ukwenza i-crimping ngokuya ngobude obushiwo be-crimping kungase kubangele ukungahambi kahle kukagesi noma ukuhlukaniswa kwekhebula.

Ubude be-crimp obuphezulu kunalokho obucacisiwe buzoholela "ekugwemeni okuphansi," lapho ucingo luzokhululeka khona ngaphansi kwe-tension. Uma inani liphansi kunevelu eshiwo, lizoholela "ekuboshweni okweqile", futhi umqhubi we-copper-clad uzosika intambo ewumgogodla, abangele ukulimala kwentambo ewumgogodla.

Ubude be-crimping kuphela umbandela wokubheka isimo seshethi kanye nentambo eyinhloko. Eminyakeni yamuva nje, esimweni sokuncishiswa okuncane kwamahhanisi ezintambo kanye nokwehlukahlukana kwezinto ezisetshenziswayo, ukutholwa komthamo wesimo sezintambo eziwumgogodla we-crimp terminal cross-section kube ubuchwepheshe obubalulekile ukuze kutholwe ngokuphelele amaphutha ahlukahlukene enqubweni yokugebenga.

Izinto zokuhlola ukubukeka kwe-pressure welding

Faka intambo eyisishebo esikhaleni bese uyixhuma kutheminali. Lapho ucingo lufakiwe, i-sheath izothintana futhi igwazwe yi-blade efakwe ku-slit, idale i-conductivity futhi isuse isidingo sokususa i-sheath.

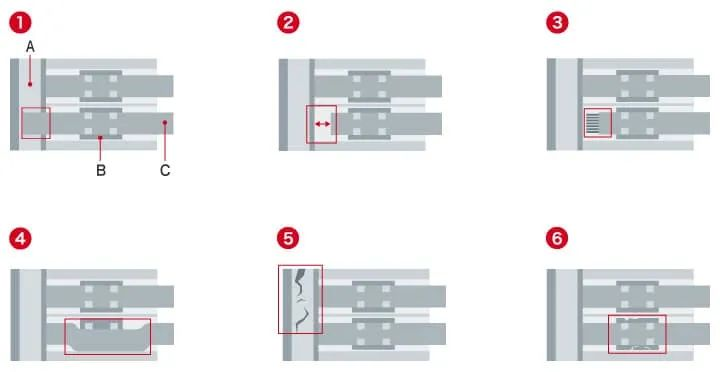

[Izinto zokuhlola ukubukeka]

(1) Intambo yinde kakhulu

(2) Igebe phezulu kocingo

(3) Amakhondaktha aphumela ngaphandle nangemuva kwamaphedi asodayo

(4) Isikhungo sokushisela i-pressure offset

(5) Ukukhubazeka kwekhava yangaphandle

(6) Amaphutha kanye nokuguqulwa kweshidi lokushisela

A: ikhava yangaphandle

B: Ishidi lokushisela

C: Ucingo

Izinto zokuhlola ukubukeka kwe-welding

Umumo wetheminali omele nezindlela zomzila wekhebula zingahlukaniswa ngokuthi "uhlobo lwesikhala sethini" kanye "nohlobo lwembobo eyindilinga". Olokuqala ludlula intambo kutheminali, bese kuthi eyakamuva idlule intambo embobeni.

[Izinto zokuhlola ukubukeka]

(1) Izintambo eziwumgogodla ziyaphumela ngaphandle

(2) Ukungahambi kahle kwe-solder (ukufudumeza okunganele)

(3) Ibhuloho le-solder (i-solder eningi)

Amacala okusebenza okuhlolwa nokuhlolwa kokubukeka kwezintambo zokubopha

Ngokwenziwa okuncane kwamahhanisi ezintambo, ukuhlolwa kokubukeka nokuhlola okusekelwe ekuqapheliseni okukhulisiwe kuba nzima nakakhulu.

Uhlelo lukaKeyence lwe-ultra-high-definition lwe-4K digital microscope "lungathuthukisa kakhulu ukusebenza kahle ngenkathi lufinyelela ukubhekwa kokukhulisa izinga eliphezulu, ukuhlolwa kokubukeka nokuhlola."

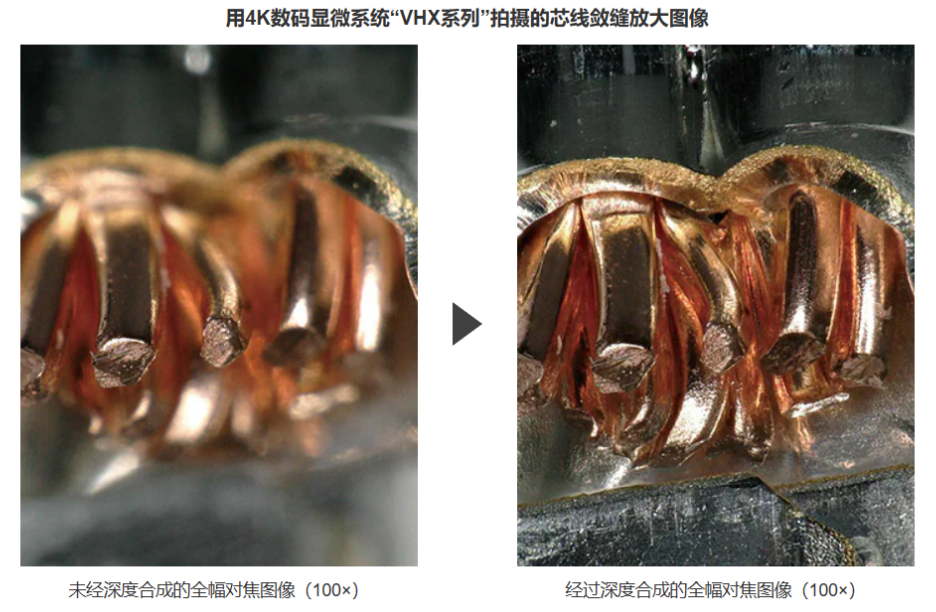

Ukujula kokuhlanganiswa kohlaka olugcwele kugxila ezintweni ezinezinhlangothi ezintathu

Intambo yokubopha iyinto enezinhlangothi ezintathu futhi ingagxilwa endaweni kuphela, okwenza kube nzima ukwenza ukubheka okuphelele nokuhlola okuhlanganisa yonke into okuqondiwe.

Isistimu yesibonakhulu se-4K yedijithali ye-"VHX series" ingasebenzisa umsebenzi "wokuzulazula wesikhathi sangempela" ukwenza ngokuzenzakalela ukuhlanganiswa kokujula nokuthwebula izithombe ze-4K ezinencazelo ephezulu kakhulu ngokugxila ngokuphelele kukho konke okuqondiwe, okwenza kube lula ukwenza ukubhekwa kokukhulisa okulungile nokuphumelelayo, ukuhlola ukubukeka kanye nokulinganisa.

Isilinganiso se-wap of wire harness

Lapho kukala, akufanele kusetshenziswe isibonakhulu kuphela, kodwa kufanele kusetshenziswe nezinye izinsimbi zokulinganisa ezihlukahlukene. Inqubo yokulinganisa inzima, idla isikhathi futhi idinga abasebenzi. Ukwengeza, amanani alinganisiwe awakwazi ukurekhoda ngokuqondile njengedatha, futhi kunezinkinga ezithile mayelana nokusebenza kahle nokuthembeka.

I-4K digital microscope system "VHX series" ifakwe amathuluzi anhlobonhlobo "esikali se-two-dimensional dimensional". Lapho ukala idatha ehlukahlukene njenge-engeli yehhanisi lezintambo kanye nokuphakama kwesigaba esiphambanayo setheminali ecijile, ukulinganisa kungaqedelwa ngemisebenzi elula. Ukusebenzisa i-"VHX Series", awukwazi ukufeza izilinganiso zobuningi kuphela, kodwa futhi ulondoloze futhi uphathe idatha efana nezithombe, amanani amanani, nezimo zokudubula, ukuthuthukisa kakhulu ukusebenza kahle komsebenzi. Ngemva kokuqeda umsebenzi wokulondoloza idatha, usengakhetha izithombe ezedlule ku-albhamu ukuze wenze umsebenzi wokulinganisa owengeziwe ezindaweni namaphrojekthi ahlukahlukene.

Ukulinganisa i-angle ye-warpage ye-wire harness kusetshenziswa i-4K digital microscope system "VHX series"

Usebenzisa amathuluzi ahlukahlukene "we-2D Dimension Measurement", ungakwazi ukuqedela kalula izilinganiso zobuningi ngokuchofoza i-engeli elungile.

Ukubhekwa kwe-core wire caulking okungathintwa i-metal surface gloss

Ethintwa ukubonakaliswa okuvela endaweni yensimbi, ukubhekwa kungase kwenzeke ngezinye izikhathi.

Uhlelo lwe-4K lwe-digital microscope "VHX series" lufakwe "i-halo elimination" kanye nemisebenzi "yokususwa kwe-halo yonyaka", engasusa ukuphazamiseka kokubonakala okubangelwa ukucwebezela kwendawo yensimbi futhi ibuke ngokunembile futhi ibambe isimo sokugoqa sentambo ewumgogodla.

Sondeza ingxenye ye-caulking yehhanisi lezintambo

Ingabe uke wazibonela ukuthi kunzima ukugxila ngokunembile ezintweni ezincane ezinezinhlangothi ezintathu ezifana ne-wire harness caulking ngesikhathi sokuhlolwa kokubukeka? Lokhu kwenza kube nzima kakhulu ukubona izingxenye ezincane nemihuzuko emihle.

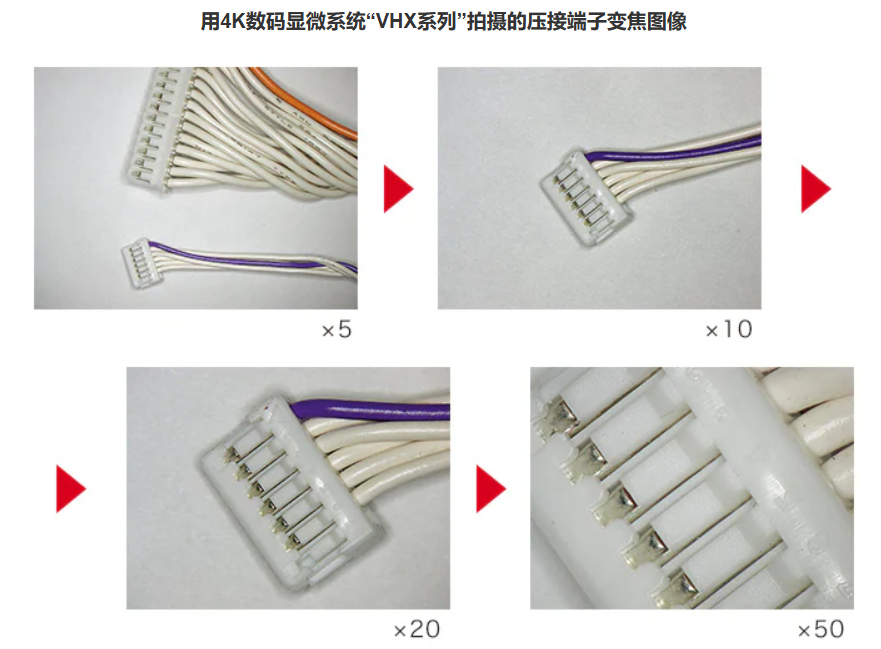

Isistimu yesibonakhulu se-4K yedijithali "i-VHX Series" ifakwe isiguquli selensi enenjini kanye nelensi ye-HR enesinqumo esiphezulu, ekwazi ukuguqulwa okuzenzakalelayo kokukhulisa ukusuka ku-20 kuya ku-6000 izikhathi ukuze kuzuzwe "ukusondeza okungenamthungo." Vele wenze imisebenzi elula ngegundane noma isilawuli esiseduze, futhi ungakwazi ukuqedela ngokushesha ukubonwa kwe-zoom.

Isistimu yokubuka eyindingilizi ebona ukubhekwa okusebenzayo kwezinto ezinohlangothi-ntathu

Uma ubheka ukubukeka kwemikhiqizo enezinhlangothi ezintathu njengamahhanisi ezintambo, ukusebenza kokushintsha i-engeli yento eqondiwe bese kulungiswa kufanele kuphindwe, futhi ukugxila kufanele kulungiswe ngokuhlukana kwe-engeli ngayinye. Akukhona nje kuphela ukuthi ingagxila endaweni kuphela, futhi kunzima ukuyilungisa, futhi kukhona ama-engeli angenakubonwa.

Isistimu yesibonakhulu sedijithali ye-4K "i-VHX series" ingasebenzisa "isistimu yokubuka yonke indawo" kanye "nesiteji sikagesi esinembe kakhulu X, Y, Z" ukuze inikeze ukusekela kokunyakaza okuguquguqukayo kwekhanda lenzwa kanye nesiteji okungenakwenzeka ngezinye izibonakhulu. .

Idivayisi yokulungisa ivumela ukulungiswa okulula kwama-eksisi amathathu (inkambu yokubuka, i-axis yokuzungezisa, ne-axis etshekile), okuvumela ukubuka okuvela kuma-engeli ahlukahlukene. Ngaphezu kwalokho, ngisho noma itshekile noma izungezisiwe, ngeke ibalekele indawo yokubuka futhi igcine okuqondiwe kumaphakathi. Lokhu kuthuthukisa kakhulu ukusebenza kahle kokubuka ukubukeka kwezinto ezinohlangothi-ntathu.

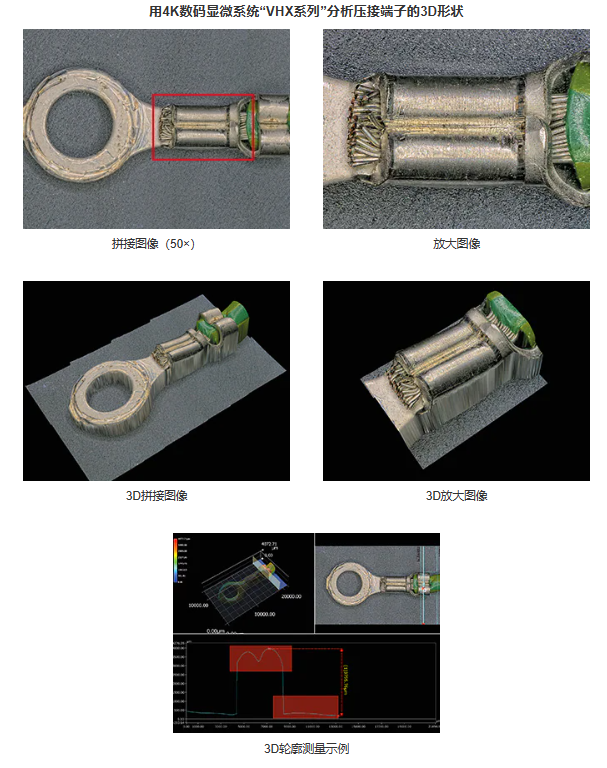

Ukuhlaziywa komumo we-3D okuvumela ukuhlolwa kwenani lamatheminali e-crimp

Uma ubheka ukubukeka kwamatheminali acijile, akudingekile kuphela ukuthi ugxile endaweni okuqondiwe kuyo-ntathu, kodwa futhi kukhona izinkinga ezifana nokugejiwe okungavamile kanye nokuchezuka kokuhlola komuntu. Kokuqondiwe kwezinhlangothi ezintathu, kungahlolwa kuphela ngezilinganiso zezinhlangothi ezimbili.

Isistimu yesibonakhulu sedijithali ye-4K "uchungechunge lwe-VHX" ayikwazi kuphela ukusebenzisa izithombe ezicacile ze-4K ukuze ibonwe okukhulisiwe kanye nokulinganisa usayizi wezinhlangothi ezimbili, kodwa ingathwebula umumo we-3D, yenza ukulinganisa kosayizi wezinhlangothi ezintathu, futhi yenze isilinganiso sekhonta esigabeni ngasinye esiphambene. Ukuhlaziywa nokukalwa komumo we-3D kungaqedelwa ngokusebenzisa imisebenzi elula ngaphandle komsebenzisi osebenza ngekhono. Ingakwazi kanyekanye ukuzuza ukuhlolwa okuthuthukisiwe nokulingene kokubukeka kwamatheminali acijile futhi ithuthukise ukusebenza kahle komsebenzi.

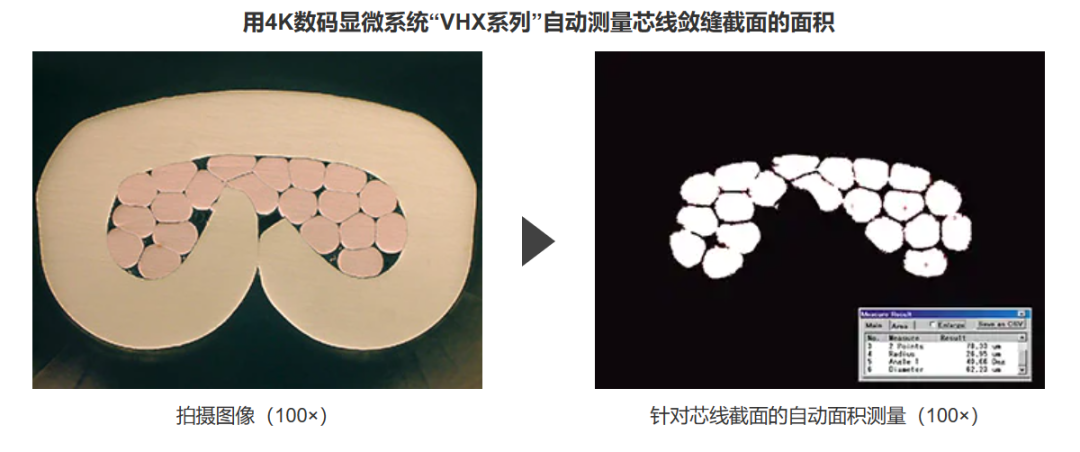

Ukulinganisa okuzenzakalelayo kwezigaba zekhebula elikhonjiwe

Isistimu yesibonakhulu se-4K yedijithali "uchungechunge lwe-VHX" lungasebenzisa amathuluzi okulinganisa ahlukahlukene ukuze kuqedelwe kalula ukulinganisa okuzenzakalelayo okuhlukahlukene kusetshenziswa izithombe ezithwetshuliwe ezinezingxenye ezihlukene.

Isibonelo, njengoba kukhonjisiwe emfanekisweni ongezansi, kungenzeka ukulinganisa ngokuzenzakalelayo kuphela indawo ye-core wire crimped cross section. Ngale misebenzi, kuyenzeka ukuthola ngokushesha nangokwesilinganiso isimo socingo oluwumongo lwengxenye ye-caulking engakwazi ukubanjwa ngokulinganisa ubude be-crimping kanye nokubhekwa kwezigaba kuphela.

Amathuluzi amasha okuphendula ngokushesha izidingo zemakethe

Ngokuzayo, isidingo semakethe samahhanisi ezintambo sizokhula. Ukuze kuhlangatshezwane nezidingo zemakethe ezikhulayo, ucwaningo olusha nentuthuko, amamodeli okuthuthukisa ikhwalithi kanye nezinqubo zokukhiqiza kufanele zisungulwe ngokusekelwe kudatha yokuthola esheshayo nenembile.

Isikhathi sokuthumela: Dec-26-2023