Ukubuka konke kwesixhumi samandla kagesi aphezulu

Izixhumi ezinama-voltage aphezulu, ezaziwa nangokuthi izixhumi zamandla kagesi aphezulu, ziwuhlobo lwesixhumi sezimoto. Ngokuvamile zibhekisela kwizixhumi ezine-voltage yokusebenza engaphezu kuka-60V futhi zibophezele kakhulu ukudlulisa amaza amakhulu.

Izixhumi ezinama-voltage aphezulu zisetshenziswa ikakhulukazi kumasekhethi aphezulu kanye namanje aphezulu ezimoto zikagesi. Basebenza ngezintambo ukuthutha amandla ephakethe lebhethri ngamasekethe kagesi ahlukene ukuya ezingxenyeni ezihlukahlukene zesistimu yemoto, njengamaphakethe ebhethri, izilawuli zezimoto, neziguquli ze-DCDC. izingxenye zamandla kagesi aphezulu njengeziguquli namashaja.

Njengamanje, kunezinhlelo ezintathu eziyinhloko ezijwayelekile zezixhumi ezinamandla kagesi, okuyi-LV standard plug-in, i-USCAR standard plug-in, kanye ne-Japanese plug-in. Kulawa ma-plug-in amathathu, i-LV njengamanje inokusabalalisa okukhulu emakethe yasekhaya kanye namazinga enqubo aphelele kakhulu.

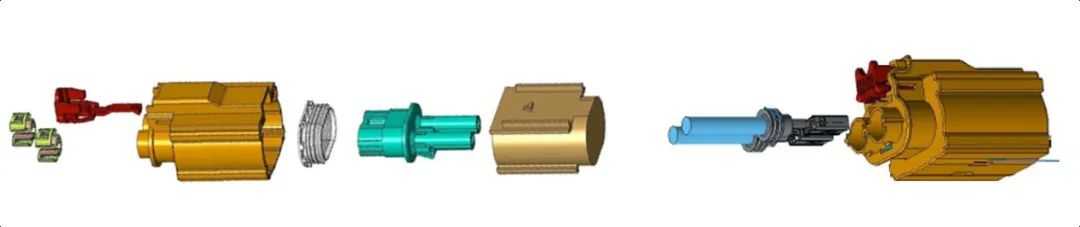

Umdwebo wenqubo yokuhlanganisa i-voltage ephezulu

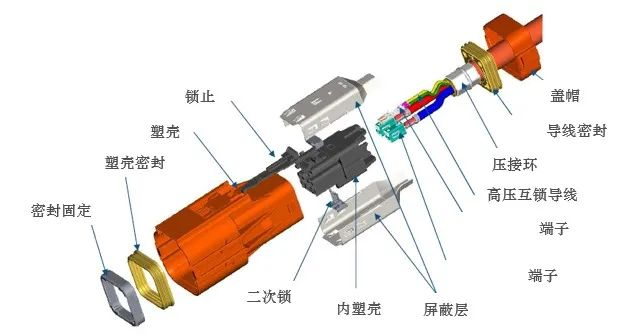

Isakhiwo esiyisisekelo sesixhumi samandla kagesi aphezulu

Izixhumi ezinama-voltage aphezulu ikakhulukazi zakhiwe izakhiwo ezine eziyisisekelo, okuyizixhumi, izivikeli, amagobolondo epulasitiki nezinye izinto.

(1) Oxhumene nabo: izingxenye eziwumgogodla eziqedela ukuxhumana kukagesi, okuyizikhumulo zabesilisa nabesifazane, umhlanga, njll.;

(2) I-insulator: isekela othintana nabo futhi iqinisekisa ukwahlukanisa phakathi koxhumana nabo, okungukuthi, igobolondo lepulasitiki elingaphakathi;

(3) Igobolondo lePlastiki: Igobolondo lesixhumi liqinisekisa ukuqondanisa kwesixhumi futhi livikela sonke isixhumi, okungukuthi, igobolondo lepulasitiki langaphandle;

(4) Izesekeli: okufaka izinsiza zesakhiwo kanye nezinsiza zokufaka, okuyizikhonkwane zokubeka indawo, izikhonkwane zomhlahlandlela, izindandatho zokuxhuma, izindandatho zokuvala, izinsimbi ezizungezayo, izakhiwo zokukhiya, njll.

Isixhumi sikagesi esiphezulu siqhume ukubuka

Ukuhlukaniswa kwezixhumi zamandla kagesi aphezulu

Izixhumi zamandla kagesi aphezulu zingahlukaniswa ngezindlela eziningi. Ukuthi isixhumi sinomsebenzi ovikelayo, inombolo yezikhonkwane zokuxhuma, njll. zonke zingasetshenziswa ukuchaza ukuhlukaniswa kwesixhumi.

1.Ukuthi kukhona ukuvikeleka noma cha

Izixhumi ezinama-voltage aphezulu zihlukaniswe ngezixhumi ezingavikelekile nezixhumi ezivikelekile ngokuya ngokuthi zinemisebenzi yokuvikela.

Izixhumi ezingavikelekile zinesakhiwo esilula, azikho umsebenzi wokuvikela, kanye nezindleko eziphansi uma kuqhathaniswa. Isetshenziswa ezindaweni ezingadingi ukuvikela, njengezinto zikagesi ezimbozwe amakesi ensimbi njengamasekhethi okushaja, ingaphakathi lephakethe lebhethri, nokulawula kwangaphakathi.

Izibonelo zezixhumi ezingenasendlalelo esivikelayo futhi ezingenazo idizayini yokukhiya okunogesi ophezulu

Izixhumi ezivikelekile zinezakhiwo eziyinkimbinkimbi, izidingo zokuvikela, nezindleko eziphakeme uma kuqhathaniswa. Ilungele izindawo lapho kudingeka khona umsebenzi wokuvikela, njengalapho ingaphandle lezinto zikagesi lixhunywe kumahhanisi ezintambo ezinamandla kagesi.

Isixhumi esinesihlangu nomklamo we-HVIL Isibonelo

2. Inombolo yamapulaki

Izixhumi ezinama-voltage aphezulu zihlukaniswa ngokuya ngenombolo yezimbobo zokuxhuma (i-PIN). Njengamanje, ezisetshenziswa kakhulu isixhumi se-1P, isixhumi se-2P nesixhumi se-3P.

Isixhumi se-1P sinesakhiwo esilula nezindleko eziphansi. Ihlangabezana nezidingo zokuvikela nokuvinjelwa kwamanzi zamasistimu anamandla kagesi aphezulu, kodwa inqubo yokuhlanganisa iyinkimbinkimbi kancane futhi ukusebenza kabusha akukuhle. Isetshenziswa ngokujwayelekile kumaphakethe ebhethri namamotho.

Izixhumi ze-2P ne-3P zinezakhiwo eziyinkimbinkimbi nezindleko eziphakeme uma kuqhathaniswa. Ihlangabezana nezidingo zokuvikela nokuvinjelwa kwamanzi kwezinhlelo zamandla kagesi aphezulu futhi inokugcinwa okuhle. Ivamise ukusetshenziselwa okokufaka nokukhiphayo kwe-DC, njengamaphekhi ebhethri anamandla kagesi, amatheminali esilawuli, amatheminali aphumayo eshaja ye-DC, njll.

1P/2P/3P isibonelo se-voltage ephezulu

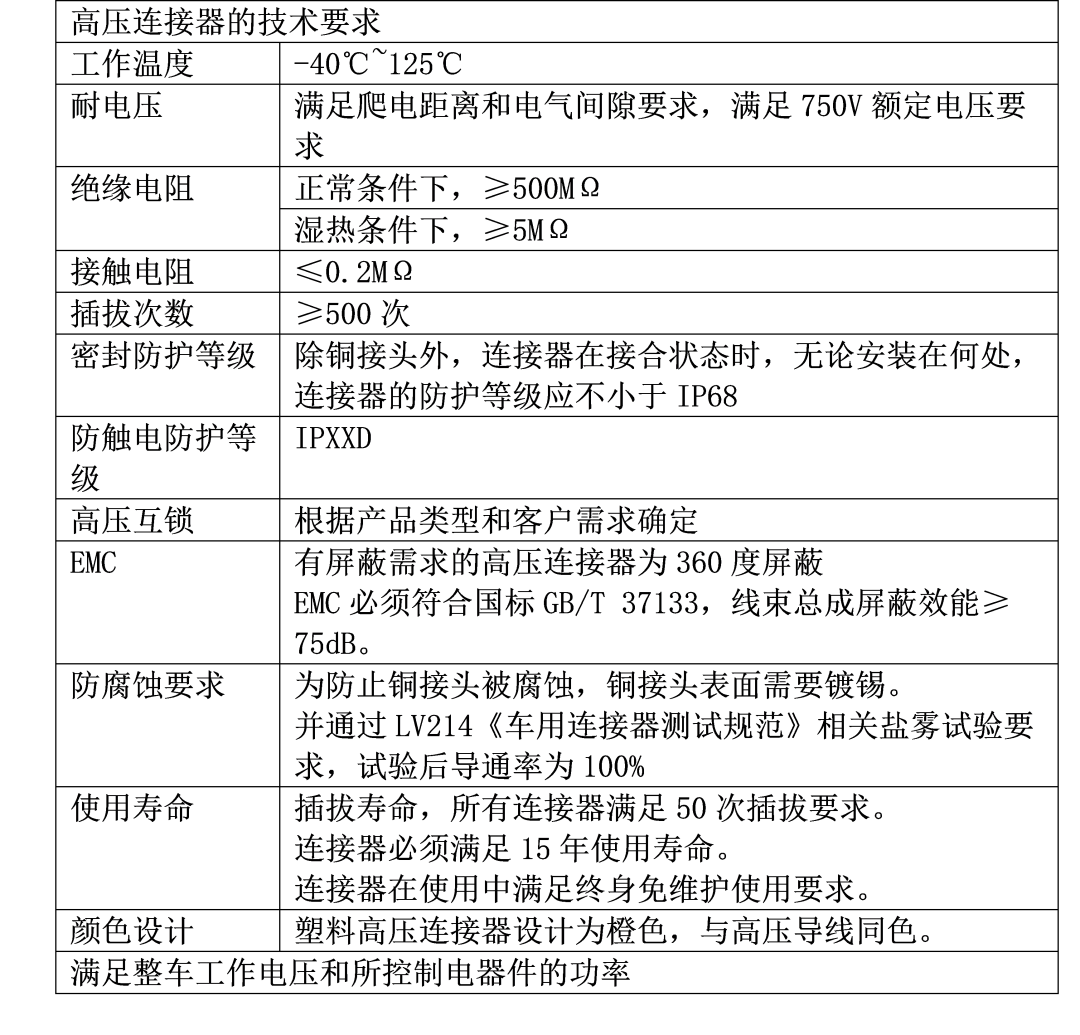

Izidingo ezijwayelekile zezixhumi zamandla kagesi aphezulu

Izixhumi zamandla kagesi aphezulu kufanele zihambisane nezidingo ezicaciswe yi-SAE J1742 futhi zibe nalezi zidingo zobuchwepheshe ezilandelayo:

Izidingo zobuchwepheshe ezicaciswe yi-SAE J1742

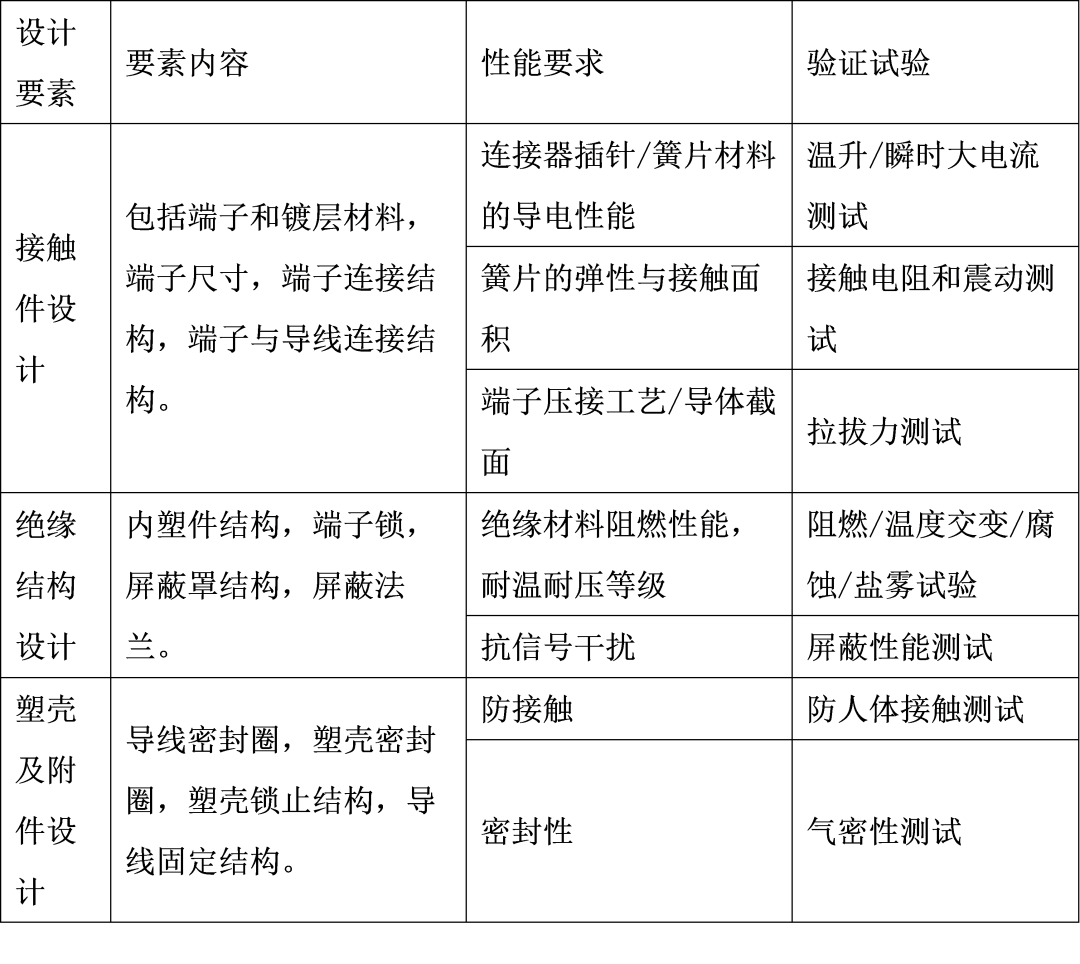

Izakhi zomklamo wezixhumi zama-voltage aphezulu

Izidingo zezixhumi zamandla kagesi aphezulu ezinhlelweni zamandla kagesi aphezulu zihlanganisa kodwa azikhawulelwe kulokhu: ugesi ophezulu nokusebenza kwamanje okuphezulu; isidingo sokukwazi ukuzuza amazinga aphezulu okuvikela ngaphansi kwezimo ezihlukahlukene zokusebenza (ezifana nezinga lokushisa eliphezulu, ukudlidliza, umthelela wokungqubuzana, ukuvikela uthuli nokungangeni kwamanzi, njll.); Yiba nokufakeka; ube nokusebenza okuhle kokuvikela i-electromagnetic; izindleko kufanele zibe phansi ngangokunokwenzeka futhi zihlale isikhathi eside.

Ngokwezici ezingenhla kanye nezidingo okufanele izixhumi ze-high-voltage kufanele zibe nazo, ekuqaleni kokuklanywa kwezixhumi ze-voltage ephezulu, izici ezilandelayo zokuklama zidinga ukucatshangelwa futhi umklamo ohlosiwe kanye nokuqinisekiswa kokuhlolwa kuyenziwa.

Uhlu lokuqhathanisa lwezakhi zomklamo, ukusebenza okuhambisanayo nokuhlolwa kokuqinisekisa kwezixhumi ezinamandla kagesi

Ukuhlaziywa kokwehluleka kanye nezinyathelo ezihambisanayo zezixhumi zamandla kagesi aphezulu

Ukuze kuthuthukiswe ukwethembeka komklamo wesixhumi, imodi yokwehluleka kwayo kufanele iqale ihlaziywe ukuze umsebenzi wokuklama ohambisanayo wokuvimbela wenziwe.

Izixhumi zivame ukuba nezinhlobo ezintathu eziyinhloko zokuhluleka: ukuthintana okungalungile, ukungezwani kahle, nokulungisa okuxekethile.

(1) Ngokuthintana kabi, izinkomba ezifana nokumelana nokuxhumana okumile, ukumelana nokuxhumana okuguquguqukayo, amandla okuhlukanisa imbobo eyodwa, izindawo zokuxhuma kanye nokumelana nokudlidliza kwezingxenye kungasetshenziswa ukwahlulela;

(2) Ngokufaka ukufakwa okungekuhle, ukumelana nokufakwa kwe-insulator, izinga lokuwohloka kwesikhathi se-insulator, izinkomba zosayizi we-insulator, abathintwayo nezinye izingxenye zingatholwa ukuze kwahlulelwe;

(3) Ukuze kube nokwethembeka kohlobo olungaguquki noluhlukanisiwe, ukubekezelelana komhlangano, umzuzu wokubekezela, amandla okugcina iphinikhodi axhumayo, amandla okufaka iphinikhodi, amandla okugcina ngaphansi kwezimo zokucindezeleka kwemvelo nezinye izinkomba zetheminali nesixhumi zingahlolwa ukuze kwahlulelwe.

Ngemva kokuhlaziya izindlela eziyinhloko zokwehluleka kanye namafomu okuhluleka kwesixhumi, izinyathelo ezilandelayo zingathathwa ukuze kuthuthukiswe ukwethembeka komklamo wokuxhuma:

(1) Khetha isixhumi esifanele.

Ukukhethwa kwezixhumi akufanele kucabangele kuphela uhlobo kanye nenani lamasekethe axhunyiwe, kodwa futhi kube lula ukubunjwa kwemishini. Isibonelo, izixhumi eziyindilinga azithintwa kancane isimo sezulu kanye nezici zemishini kunezixhumi eziwunxande, zinokuguga okuncane komshini, futhi zixhunywe ngokuthembekile emikhawulweni yezintambo, ngakho-ke izixhumi eziyindilinga kufanele zikhethwe ngangokunokwenzeka.

(2) Uma likhulu inani loxhumana nabo kusixhumi, kunciphisa ukwethembeka kwesistimu. Ngakho-ke, uma isikhala nesisindo sivumela, zama ukukhetha isixhumi esinenombolo encane yoxhumana nabo.

(3) Lapho kukhethwa isixhumi, izimo zokusebenza zemishini kufanele zicatshangelwe.

Lokhu kungenxa yokuthi isamba somthwalo wamanje kanye namandla aphezulu okusebenza kwesixhumi ngokuvamile anqunywa ngokusekelwe ekushiseni okuvunyelwe lapho kusebenza ngaphansi kwezimo eziphezulu zokushisa zendawo ezungezile. Ukuze kuncishiswe izinga lokushisa lokusebenza kwesixhumi, izimo zokushisa ukushisa kwesixhumi kufanele zicatshangelwe ngokugcwele. Isibonelo, abathintwayo abakude ukusuka enkabeni yesixhumi bangasetshenziswa ukuze kuxhunywe ukunikezwa kwamandla, okulungele kakhulu ukuqeda ukushisa.

(4) Ingangeni manzi futhi ingagqwali.

Lapho isixhumi sisebenza endaweni enamagesi agqwalayo kanye noketshezi, ukuze kuvinjelwe ukugqwala, kufanele kuqashelwe ukuthi kungenzeka ukuyifaka ivundlile ukusuka ohlangothini ngesikhathi sokufakwa. Uma izimo zidinga ukufakwa okuqondile, uketshezi kufanele luvinjwe ukuthi lungagelezi lungene kusixhumi ngemikhondo. Ngokuvamile sebenzisa izixhumi ezingangeni manzi.

Amaphuzu abalulekile ekwakhiweni koxhumana nabo be-high-voltage connector

Ubuchwepheshe bokuxhumanisa othintana nabo ikakhulukazi buhlola indawo yokuxhumana namandla okuxhumana, okuhlanganisa ukuxhumana phakathi kwamatheminali nezintambo, nokuxhumana kokuxhumana phakathi kwamatheminali.

Ukuthembeka kwabathintwayo kuyisici esibalulekile ekunqumeni ukwethembeka kwesistimu futhi kuyingxenye ebalulekile yawo wonke umhlangano wamahhanisi ombane aphezulu.. Ngenxa yesimo esinzima sokusebenza kwamanye amatheminali, izintambo nezixhumi, ukuxhumana phakathi kwamatheminali nezintambo, nokuxhumana phakathi kwamatheminali namatheminali kujwayele ukwehluleka okuhlukahlukene, njengokugqwala, ukuguga, kanye nokuxega ngenxa yokudlidliza.

Njengoba ukwehluleka kwezintambo zikagesi okubangelwa ukulimala, ukuxega, ukuwa, kanye nokwehluleka kothintana nabo benza ukwehluleka okungaphezu kuka-50% kulo lonke uhlelo lukagesi, ukunakwa okugcwele kufanele kukhokhwe ekwakhiweni kokwethembeka kothintana nabo ekwakhiweni kokwethembeka kohlelo lukagesi olunamandla kagesi wemoto.

1. Ukuxhumana kokuxhumana phakathi kwetheminali nocingo

Ukuxhumana phakathi kwamatheminali nezintambo kubhekisela ekuxhumekeni phakathi kwalokhu okubili ngenqubo ye-crimping noma inqubo ye-welding ye-ultrasonic. Njengamanje, inqubo ye-crimping kanye nenqubo ye-welding ye-ultrasonic ivame ukusetshenziswa kumahhanisi wezintambo ezinama-voltage aphezulu, ngalinye linezinzuzo zalo kanye nokubi.

(1) Inqubo ye-crimping

Umgomo wenqubo ye-crimping ukusebenzisa amandla angaphandle ukuze uvele ucindezele ngokomzimba intambo kakhondatha engxenyeni eboshiwe yetheminali. Ubude, ububanzi, isimo esihlukanisayo kanye namandla okudonsa e-terminal crimping yingqikithi yokuqukethwe kwekhwalithi ye-terminal crimping, enquma ikhwalithi ye-crimping.

Kodwa-ke, kufanele kuqashelwe ukuthi i-microstructure yanoma iyiphi indawo eqinile ecutshungulwe kahle ihlale ilukhuni futhi ingalingani. Ngemuva kokuthi amatheminali nezintambo zicishiwe, akukhona ukuthintana kwayo yonke indawo yokuxhumana, kodwa ukuxhumana kwamanye amaphuzu ahlakazekile endaweni yokuxhumana. , indawo yokuxhumana yangempela kufanele ibe yincane kunendawo yokuxhumana yethiyori, okuyisizathu futhi ukuthi kungani ukuphikiswa kokuxhumana kwenqubo ye-crimping kuphezulu.

I-crimping yemishini ithintwa kakhulu inqubo yokugoqa, njengokucindezela, ukuphakama kwe-crimping, njll. Ukulawulwa kokukhiqiza kudinga ukwenziwa ngezindlela ezinjengobude be-crimping nokuhlaziywa kwephrofayili/ukuhlaziywa kwe-metallographic. Ngakho-ke, ukungaguquguquki kwe-crimping yenqubo ye-crimping kuyisilinganiso futhi ukugqokwa kwamathuluzi Umthelela mkhulu futhi ukwethembeka kumaphakathi.

Inqubo ye-crimping ye-crimping yemishini ivuthiwe futhi inezinhlobonhlobo zezinhlelo zokusebenza ezingokoqobo. Kuyinqubo yendabuko. Cishe bonke abahlinzeki abakhulu banemikhiqizo yokubopha izintambo esebenzisa le nqubo.

Amaphrofayili wokuxhumana wetheminali nawentambo usebenzisa inqubo ye-crimping

(2) Inqubo ye-welding ye-ultrasonic

I-Ultrasonic welding isebenzisa amaza okudlidliza anemvamisa ephezulu ukuze idlulisele ezindaweni ezimbili ezizoshiselwa. Ngaphansi kwengcindezi, izindawo ezingaphezulu zezinto ezimbili ziyagudlana ukuze zakhe ukuhlangana phakathi kwezingqimba zamangqamuzana.

I-Ultrasonic welding isebenzisa ijeneretha ye-ultrasonic ukuguqula i-50/60 Hz yamanje ibe ngu-15, 20, 30 noma 40 KHz amandla kagesi. Amandla kagesi we-high-frequency aguqulwa futhi abe ukunyakaza komshini wemvamisa efanayo nge-transducer, bese ukunyakaza komshini kudluliselwa ekhanda lokushisela ngokusebenzisa isethi yamadivayisi wezimpondo ezingashintsha i-amplitude. Ikhanda lokushisela lidlulisela amandla okudlidliza atholiwe ekuhlanganyeleni kwendawo yokusebenza ukuze ishiselwe. Kule ndawo, amandla okudlidliza aguqulwa abe amandla okushisa ngokungqubuzana, ancibilikise insimbi.

Mayelana nokusebenza, inqubo ye-welding ye-ultrasonic inokumelana okuncane kokuxhumana nokushisa okuphansi kwe-overcurrent isikhathi eside; mayelana nokuphepha, inokwethenjelwa futhi akulula ukuyikhulula futhi iwe ngaphansi kokudlidliza kwesikhathi eside; ingasetshenziselwa ukushisela phakathi kwezinto ezahlukene; kuthintwa i-oxidation ebusweni noma ukunamathela Okulandelayo; ikhwalithi yokushisela ingahlulelwa ngokuqapha ama-waveforms afanele wenqubo ye-crimping.

Nakuba izindleko zemishini yenqubo ye-welding ye-ultrasonic ziphakeme ngokuqhathaniswa, futhi izingxenye zensimbi okufanele zishiselwe azikwazi ukushuba kakhulu (ngokuvamile ≤5mm), ukushisela kwe-ultrasonic kuyinqubo yomshini futhi akukho ukugeleza kwamanje phakathi nayo yonke inqubo yokushisela, ngakho-ke azikho Izinkinga zokuqhuba ukushisa nokumelana nokumelana yizimo zesikhathi esizayo ze-high-voltage wire harness welding.

Amatheminali kanye nama-conductor ane-welding ye-ultrasonic kanye nezigaba zabo zokuxhumana

Kungakhathaliseki ukuthi inqubo ye-crimping noma inqubo ye-welding ye-ultrasonic, ngemva kokuba ukuphela kuxhunywe ocingweni, amandla ayo okudonsa kufanele ahlangabezane nezidingo ezijwayelekile. Ngemva kokuba ucingo luxhunywe kusixhumi, amandla okudonsa akumele abe ngaphansi kwamandla amancane okudonsa.

Isikhathi sokuthumela: Dec-06-2023