1.0

Ububanzi besicelo nencazelo

1.1 Ifanele imikhiqizo yochungechunge lwamashubhu olunciphayo olunodonga oluphindwe kabili lwezintambo zezimoto.

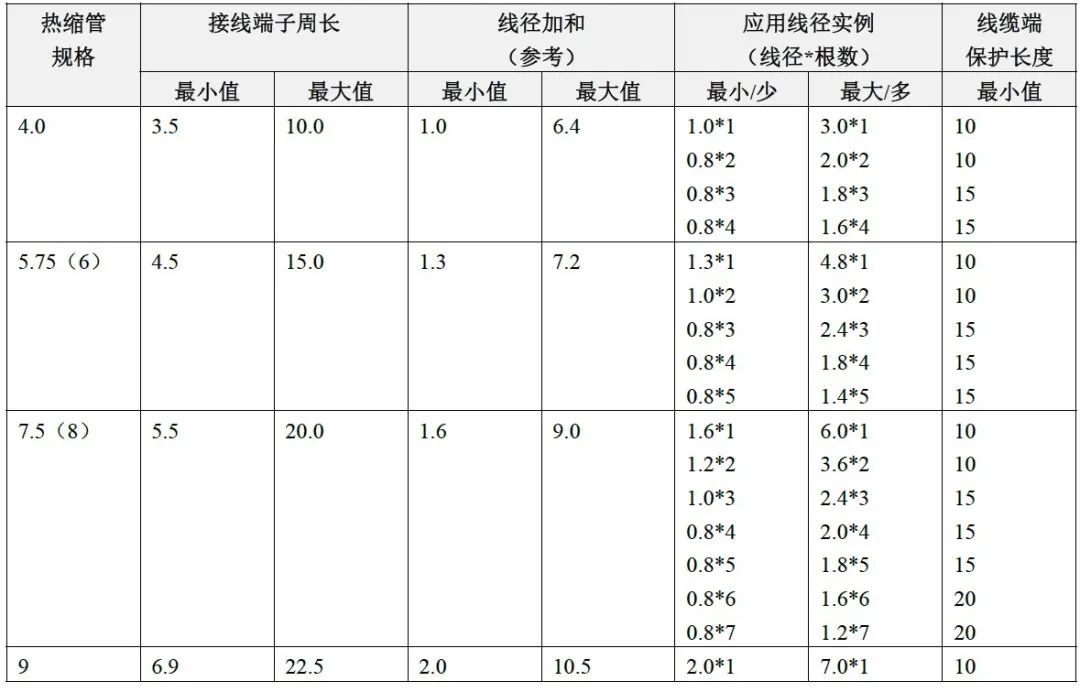

1.2 Uma isetshenziswa kumahhanisi ezintambo zezimoto, kumatheminali, izintambo zezintambo kanye nezintambo ezingangeni emanzini, imininingwane kanye nobukhulu beshubhu elishwabene nokushisa lihambisana nereferensi yobukhulu obuncane nobukhulu bobukhulu bendawo emboziwe.

2.0

Sebenzisa nokukhetha

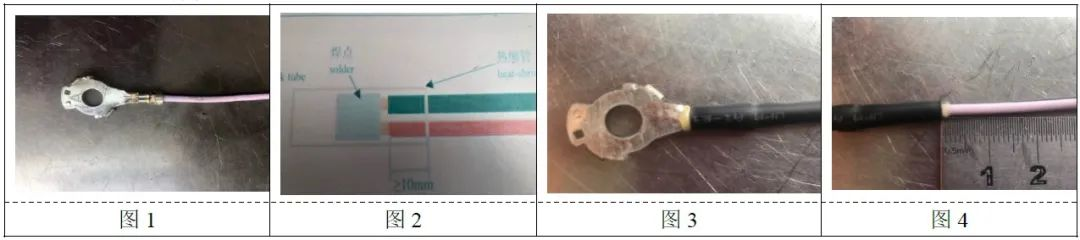

2.1 Umdwebo wezintambo zetheminali

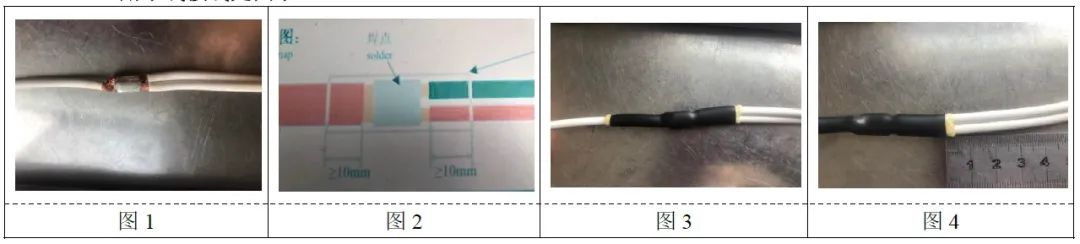

2.2 Umdwebo wokuxhuma izintambo

2.3 Imiyalo yokusetshenziswa nokukhetha

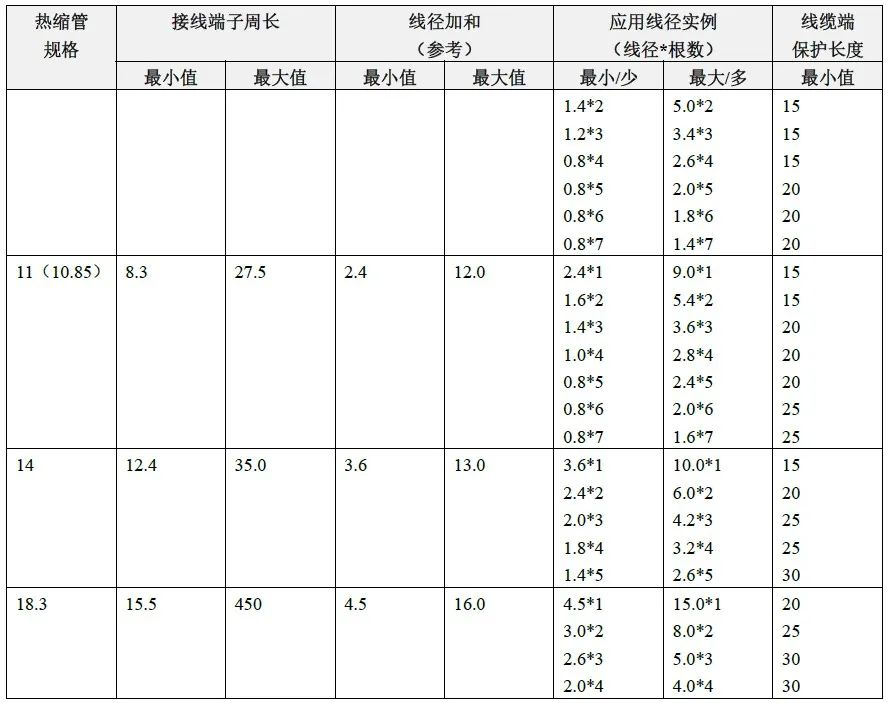

2.3.1Ngokobubanzi obuncane nobukhulu bomjikelezo wengxenye emboziwe yetheminali (ngemuva kokucwiliswa), ububanzi obuncane nobukhulu obusebenzayo bedayamitha yekhebula nenani lezintambo, khetha usayizi ofanele weshubhu lokushwabanisa ukushisa, bheka ngezansi ukuze uthole imininingwane Ithebula 1.

2.3.2Qaphela ukuthi ngenxa yezindawo ezihlukene zokusetshenziswa nezindlela, ubudlelwano bokuxhumana obunconyiwe kanye nobubanzi kuThebula 1 okokubhekisela kuphela; kuyadingeka ukunquma izincwadi ezifanele ezisekelwe ekusetshenzisweni kwangempela nasekuqinisekiseni, futhi kwakhiwe iqoqo lesizindalwazi.

2.3.3Ebudlelwaneni obuhambisanayo Kuthebula 1, "Isibonelo Sobubanzi Bentambo Yohlelo Lokusebenza" sinikeza ubuncane noma ubukhulu bedayamitha yocingo engasetshenziswa uma kunezintambo eziningi ezinobubanzi bentambo efanayo. Kodwa-ke, ekusetshenzisweni kwangempela, kunezintambo eziningi ezinobubanzi bezintambo ezihlukene ekugcineni kokuxhumana kwezintambo zocingo. Ngalesi sikhathi, ungakwazi ukuqhathanisa ikholomu "yesamba samadiamitha ezintambo" kuThebula 1. Isamba sangempela samadiamitha ezintambo kufanele sibe phakathi kwesamba sesamba samadiamitha ocingo obuncane nobukhulu, bese siqinisekisa ukuthi siyasebenza yini.

2.3.4Ukuze kufakwe izintambo zetheminali noma izintambo zocingo, isiyingi esisebenzayo noma ububanzi bentambo yobubanzi beshubhu elishwabana lokushisa elihambisanayo kudingeka kucatshangelwe, futhi kufanele ikwazi ukumboza kanyekanye ubukhulu obuncane nobukhulu (indilinga noma idiameter yentambo) yento emboziwe. Uma kungenjalo, kufanele kubekwe kuqala ekuzameni ukusebenzisa amashubhu ashwabenekayo ezinye izicaciso ukuze kubonakale ukuthi angakwazi yini ukuhlangabezana nezidingo zokusetshenziswa; okwesibili, dweba futhi ushintshe indlela yokufaka izintambo ukuze ikwazi ukuhlangabezana nezidingo ngesikhathi esifanayo; okwesithathu, engeza ifilimu noma izinhlayiya zenjoloba ekugcineni ezingakwazi ukuhlangabezana nenani eliphezulu, ubuncane Engeza ukushisa shwabanisa amashubhu ekugcineni komunye; ekugcineni, yenza ngokwezifiso umkhiqizo ofanele wokushisa wokunciphisa ukushisa noma esinye isisombululo sokuvala ukuvuza kwamanzi.

2.3.5Ubude beshubhu elishwabene ukushisa kufanele bunqunywe ngokuya ngobude bangempela bokuvikela isicelo. Kuye ngobubanzi bentambo, ishubhu lokushwabanisa ukushisa elivame ukusetshenziselwa izintambo zetheminali lingu-25mm~50mm ubude, futhi ishubhu elishwabene ukushisa elisetshenziselwa izintambo zocingo lingu-40~70mm ubude. Kutuswa ukuthi ubude bokufakwa kwekhebula lokuvikela elishwabene ukushisa kube ngu-10mm ~ 30mm, futhi kukhethwe ngokuya ngokucaciswa nobukhulu obuhlukahlukene. Bheka Ithebula 1 ngezansi ukuze uthole imininingwane. Uma ubude bokuvikela bubude, kuba ngcono umphumela wokuvala amanzi.

2.3.6Imvamisa, ngaphambi kokuthi ugeze amatheminali noma ugeqe/ushisele izintambo, faka ishubhu lokushwabanisa ukushisa ezintanjeni kuqala, ngaphandle kwendlela yokufaka izintambo ezingangeni manzi (okungukuthi, zonke izintambo zisesiphethweni esisodwa, futhi ayikho indawo yokuphuma noma itheminali ngakolunye uhlangothi) Izintambo). Ngemva kokushwabana, sebenzisa umshini wokunciphisa ukushisa, isibhamu somoya oshisayo, noma enye indlela yokushisisa ethile ukuze wenze ukuncipha kokushisisa ukuze unciphise ishubhu lokunciphisa ukushisa futhi ulilungise endaweni eklanyelwe ukuvikela.

2.3.7Ngemuva kokunciphisa ukushisa, ngokuya ngezidingo zokuklama noma zokusebenza, ukuhlolwa okubukwayo kukhethwa ukuze kuqinisekiswe ukuthi ikhwalithi yomsebenzi inhle yini. Isibonelo, hlola ukubukeka sekukonke ukuze uthole okungavamile okufana namaqhubu, ukubukeka okungalingani (okungenzeka akunciphisi ukushisa), ukuvikeleka kwe-asymmetric (indawo inyakazile), ukulimala kwendawo, njll. Naka ukugoqa nokubhoboza okubangelwa ama-jumper; hlola zombili iziphetho Ukuthi ngabe isembozo siqinile, ukuthi iglue liyachichima futhi livalwe ekugcineni kocingo kuhle (imvamisa ukuchichima kungu-2~5mm); kungakhathaliseki ukuthi ukuvikelwa kokuvala uphawu ku-terminal kuhle, nokuthi ngabe ukuchichima kweglue kudlula umkhawulo odingwa umklamo, ngaphandle kwalokho kungase kuthinte umhlangano. njll.

2.3.8Uma kudingekile noma kudingekile, ukusampula kuyadingeka ukuze kuhlolwe uphawu olungangeni manzi (umshini wokuhlola okhethekile).

2.3.9Isikhumbuzi esikhethekile: Amatheminali ensimbi aphatha ukushisa ngokushesha lapho kushisa. Uma kuqhathaniswa nezintambo ezivalekile, zimunca ukushisa okwengeziwe (izimo ezifanayo nesikhathi zimunca ukushisa okwengeziwe), ziphathe ukushisa ngokushesha (ukulahlekelwa ukushisa), futhi zisebenzise ukushisa okukhulu ngesikhathi sokushisisa nokuncipha. Ukushisa ngokwethiyori kukhulu uma kuqhathaniswa.

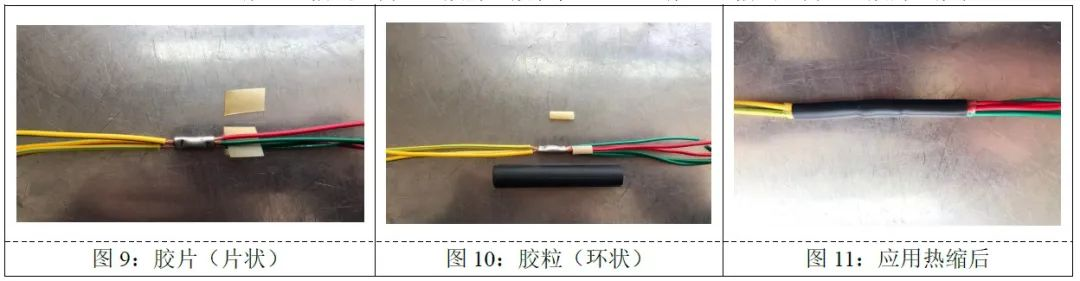

2.3.10Ngezinhlelo zokusebenza ezinobubanzi obukhulu bezintambo noma izintambo eziningi, lapho i-adhesive encibilikayo eshisayo ye-tube yokushisa iyancipha ngokwayo akwanele ukugcwalisa izikhala phakathi kwezintambo, kunconywa ukufaka izinhlayiya zenjoloba (ezimise okwendandatho) noma ifilimu (emise okweshidi) Ukwandisa inani leglue phakathi kwezintambo ukuqinisekisa umphumela wokuvala amanzi. Kunconywa ukuthi usayizi weshubhu lokunciphisa ukushisa libe ngu-≥14, ububanzi bentambo bukhulu futhi inani lezintambo likhulu (≥2), njengoba kuboniswe ku-Figure 9, 10, kanye no-11. Isibonelo, i-18.3 yokucaciswa kweshubhu elincipha ukushisa, ububanzi bentambo engu-8.0mm, izintambo ezingu-2, zidinga ukungeza ifilimu yezinhlayiya noma irabha; 5.0mm wire ububanzi, 3 izintambo, kudingeka ukwengeza ifilimu noma izinhlayiya zenjoloba.

2.4 Ithebula lokukhetha letheminali kanye nosayizi wedayamitha yezintambo ezihambisana nezicaciso zeshubhu lokuncipha kokushisa (iyunithi: mm)

3.0

Umshini wokunciphisa ukushisa kanye nomshini wokunciphisa ukushisa wamashubhu okunciphisa ukushisa amahhanisi ezintambo zezimoto

3.1 Umshini wokunciphisa ukushisa oqhubekayo wohlobo lwe-Crawler

Ezivamile zihlanganisa imishini ye-TE (Tyco Electronics) ye-M16B, M17, kanye ne-M19 yochungechunge lwemishini yokunciphisa ukushisa, i-Shanghai Rugang Automation's TH801, TH802 uchungechunge lwemishini yokunciphisa ukushisa, kanye nemishini ye-Henan Tianhai yokunciphisa ukushisa, njengoba kukhonjisiwe kuMfanekiso 12 no-13.

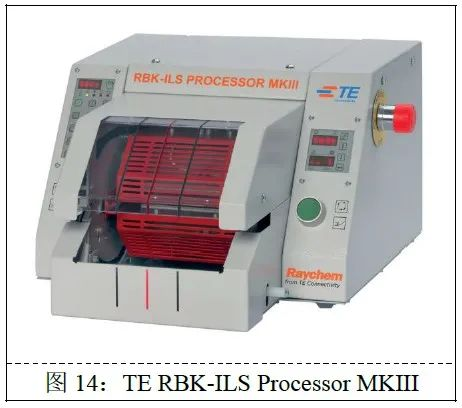

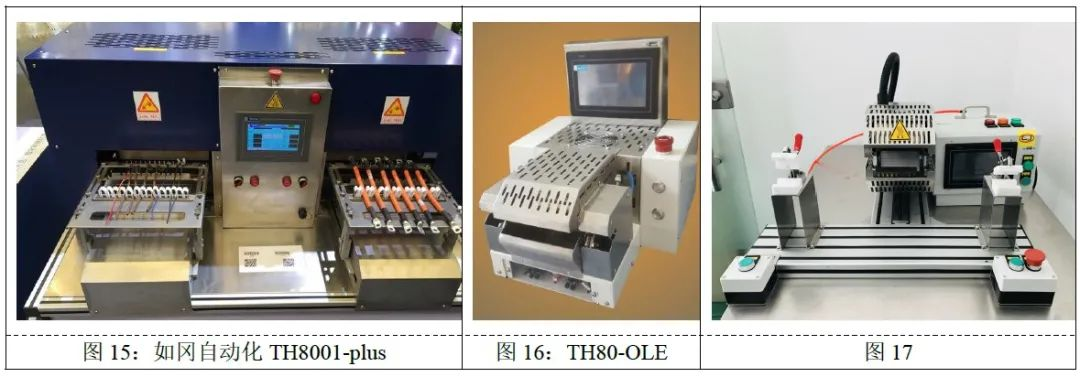

3.2 Umshini wokushwabanisa ukushisa

Ezivamile zihlanganisa umshini wokunciphisa ukushisa we-TE (Tyco Electronics) we-RBK-ILS Processor MKIII, umshini wokunciphisa ukushisa we-Shanghai Rugang Automation's TH8001-plus digital networked digital networked terminal heat shrink machine, TH80-OLE uchungechunge lomshini wokunciphisa ukushisa okuku-inthanethi, njll., njengoba kuboniswe kuMfanekiso 14, 15 no-16 obonisiwe.

3.3 Imiyalelo yokusebenza kokunciphisa ukushisa

3.3.1Izinhlobo ezingenhla zemishini yokunciphisa ukushisa yonke imishini yokunciphisa ukushisa ekhipha inani elithile lokushisa endaweni yokusebenza yomhlangano ukuze inciphise ukushisa. Ngemuva kokuthi ishubhu yokunciphisa ukushisa emhlanganweni ifinyelela ekukhuphukeni okwanele kokushisa, ishubhu le-heat shrink liyancipha futhi okunamathelayo okuncibilika okushisayo kuyancibilika. Idlala indima yokugoqa ngokuqinile, ukuvala nokukhulula amanzi.

3.3.2Ukucacisa kabanzi, inqubo yokunciphisa ukushisa empeleni iyishubhu yokunciphisa ukushisa ekuhlanganiseni. Ngaphansi kwezimo zokushisa zomshini wokunciphisa ukushisa, ithubhu yokunciphisa ukushisa ifinyelela izinga lokushisa lokunciphisa ukushisa, ishubhu le-heat shrink liyancipha, futhi okunamathelayo okuncibilika okushisayo kufinyelela izinga lokushisa lokuncibilika. , i-glue encibilikayo eshisayo igeleza ukuze igcwalise izikhala futhi inamathele ku-workpiece ehlanganisiwe, ngaleyo ndlela yenza uphawu lwekhwalithi olungangeni manzi noma ingxenye yomhlangano wokuvikela ovikelayo.

3.3.3Izinhlobo ezahlukene zemishini yokunciphisa ukushisa zinamandla ahlukene okushisa, okungukuthi, inani lokukhishwa kokushisa ku-workpiece yomhlangano ngesikhathi seyunithi, noma ukusebenza kahle kokukhipha ukushisa, kuhlukile. Ezinye ziyashesha, ezinye zihamba kancane, isikhathi sokusebenza sokunciphisa ukushisa sizohluka (umshini wokukhasa ulungisa isikhathi sokushisisa ngesivinini), futhi izinga lokushisa lempahla okudingeka lisethwe lizohluka.

3.3.4Ngisho nemishini yokunciphisa ukushisa yemodeli efanayo izoba nempumelelo ehlukene yokukhipha ukushisa ngenxa yomehluko wenani lokukhishwa kwe-heater workpiece yemishini, ubudala bemishini, njll.

3.3.5Amazinga okushisa asethiwe emishini yokunciphisa ukushisa engenhla ngokuvamile aphakathi kuka-500°C no-600°C, kuhambisana nesikhathi sokushisisa esifanele (umshini wokukhasa ulungisa isikhathi sokushisisa ngesivinini) ukuze wenze imisebenzi yokunciphisa ukushisa.

3.3.6Kodwa-ke, izinga lokushisa elimisiwe lemishini yokunciphisa ukushisa alimeli izinga lokushisa langempela elifinyelelwe umhlangano wokunciphisa ukushisa ngemva kokushisisa. Ngamanye amazwi, ishubhu yokunciphisa ukushisa kanye nezinto zokusebenza zayo zokuhlanganisa akudingeki ukuthi zifinyelele amadigri angamakhulu amaningana asethwe umshini wokunciphisa ukushisa. Ngokuvamile, zidinga ukufinyelela ekukhuphukeni kwezinga lokushisa elingu-90°C kuya ku-150°C ngaphambi kokuba zinciphe futhi zisebenze njengesivalo sokukhulula amanzi.

3.3.7Izimo zenqubo ezifanele kufanele zikhethelwe imisebenzi yokunciphisa ukushisa ngokusekelwe kusayizi weshubhu lokunciphisa ukushisa, ukuqina nokuthamba kwempahla, izici zevolumu nezici zokumunca ukushisa zento emboziwe, ivolumu nezici zokumunca ukushisa kwendawo yamathuluzi, kanye nezinga lokushisa elizungezile.

3.3.8Ngokuvamile ungasebenzisa i-thermometer futhi uyifake emgodini noma emhubheni wempahla yokunciphisa ukushisa ngaphansi kwezimo zenqubo, futhi uqaphele izinga lokushisa eliphezulu elifinyelelwa yithemometha ngesikhathi sangempela njengokulinganisa amandla okukhipha ukushisa kwempahla yokunciphisa ukushisa ngaleso sikhathi. (Qaphela ukuthi ngaphansi kwezimo ezifanayo zenqubo yokushisa ukushisa, ukukhuphuka kwezinga lokushisa kwethemometha kuzohluka ekukhuphukeni kwezinga lokushisa kwe-heat shrink workpiece yomhlangano ngenxa yomehluko wevolumu nokwenyuka kwezinga lokushisa ngemva kokufudumeza, ngakho-ke ukunyuka kwezinga lokushisa kwethemometha Ukunyuka kwezinga lokushisa okulinganiselwe kusetshenziswa kuphela njengesikali sereferensi yezimo zenqubo futhi akumeleli ukuphakama kwezinga lokushisa okuzofinyelelwa umhlangano wokunciphisa ukushisa)

3.3.9Izithombe zethemometha zikhonjiswe kuMfanekiso 18 no-19. Ngokuvamile, kudingeka ukuhlola okukhethekile kwezinga lokushisa.

Isikhathi sokuthumela: Nov-14-2023