Njengoba amakhondaktha e-aluminium esetshenziswa ngokwandayo kumahhanisi ezintambo zezimoto, lesi sihloko sihlaziya futhi sihlele ubuchwepheshe bokuxhuma amahhanisi ezintambo zamandla e-aluminium, futhi sihlaziye futhi siqhathanise ukusebenza kwezindlela ezihlukene zokuxhuma ukuze kube lula ukukhethwa kamuva kwezindlela zokuxhuma izintambo zezintambo ze-aluminium.

01 Uhlolojikelele

Ngokugqugquzelwa kokusetshenziswa kwamakhondaktha e-aluminium kumahhanisi ezintambo zezimoto, ukusetshenziswa kwamakhondatha e-aluminium esikhundleni samakhondaktha ethusi endabuko kuyanda kancane kancane. Kodwa-ke, ohlelweni lokufakwa kwezintambo ze-aluminium esikhundleni sezintambo zethusi, ukugqwala kwe-electrochemical, ukushisa okuphezulu, kanye ne-conductor oxidation yizinkinga okufanele zibhekane nazo futhi zixazululwe phakathi nenqubo yokufaka isicelo. Ngesikhathi esifanayo, ukusetshenziswa kwezintambo ze-aluminium esikhundleni sezintambo zethusi kufanele kuhlangabezane nezidingo zezintambo zokuqala zethusi. Izakhiwo zikagesi nezemishini ukuze kugwenywe ukuwohloka kokusebenza.

Ukuze kuxazululwe izinkinga ezifana nokugqwala kwe-electrochemical, ukushisa okuphezulu, kanye ne-conductor oxidation ngesikhathi kusetshenziswa izintambo ze-aluminium, okwamanje kunezindlela ezine zokuxhuma ezijwayelekile embonini, okuyilezi: i-friction welding kanye ne-pressure welding, i-friction welding, i-ultrasonic welding, kanye ne-plasma welding.

Okulandelayo ukuhlaziya kanye nokuqhathanisa ukusebenza kwezimiso zokuxhuma nezakhiwo zalezi zinhlobo ezine zokuxhuma.

02 I-friction welding kanye ne-pressure welding

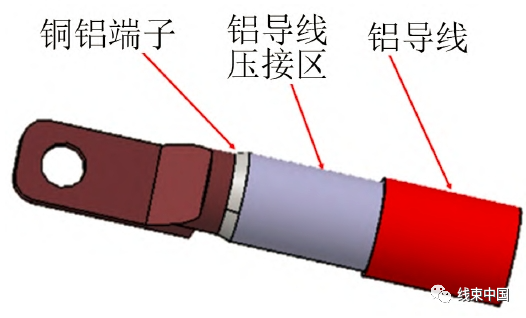

I-friction welding kanye ne-pressure joining, okokuqala sebenzisa izinti zethusi nezinduku ze-aluminium ukuze ushisele i-friction, bese ugxiviza izinti zethusi ukuze wenze ukuxhumana kukagesi. Izinti ze-aluminium zenziwe ngomshini futhi zakhiwe ukuze zakhe iziphetho ze-aluminium crimp, futhi amatheminali ethusi ne-aluminium akhiqizwa. Bese intambo ye-aluminium ishuthekwa ekugcineni kwe-aluminium crimping yetheminali yethusi-aluminium futhi igoqwe ngomshini wokuhlanganisa izintambo zezintambo zendabuko ukuze kuqedelwe ukuxhumana phakathi kwekhondakta ye-aluminium kanye netheminali yethusi-aluminium, njengoba kuboniswe kuMfanekiso 1.

Uma kuqhathaniswa namanye amafomu okuxhumana, i-friction welding kanye ne-pressure welding yakha indawo yoguquko ye-copper-aluminium alloy ngokusebenzisa i-friction welding yezinti zethusi nezinduku ze-aluminium. Indawo yokushisela ifana kakhulu futhi iminyene, igwema ngokuphumelelayo inkinga ye-thermal creep ebangelwa ama-coefficients ahlukene wokunweba okushisayo wethusi ne-aluminium. , Ngaphezu kwalokho, ukwakheka kwendawo yenguquko ye-alloy futhi kugwema ngokuphumelelayo ukugqwala kwe-electrochemical okubangelwa imisebenzi ehlukene yensimbi phakathi kwethusi ne-aluminium. Ukuvalwa okulandelayo ngamashubhu ancipha ukushisa kusetshenziswa ukuhlukanisa isifutho sikasawoti kanye nomhwamuko wamanzi, okugwema ngempumelelo ukwenzeka kokugqwala kwe-electrochemical. Ngokusebenzisa i-hydraulic crimping yocingo lwe-aluminium kanye nokuphela kwe-aluminium crimp yesiphetho se-copper-aluminium, isakhiwo se-monofilament somqhubi we-aluminium kanye nongqimba lwe-oxide odongeni lwangaphakathi lwe-aluminium crimp ekupheleni luyabhujiswa futhi luhlutshiwe, bese kubanda kuqedwa phakathi kwezintambo ezilodwa naphakathi kwe-aluminium endor conductor kanye ne-icrinner endor conductor. Inhlanganisela yokushisela ithuthukisa ukusebenza kukagesi kokuxhuma futhi inikeza ukusebenza okuthembekile kwemishini.

03 Ukushisela i-friction

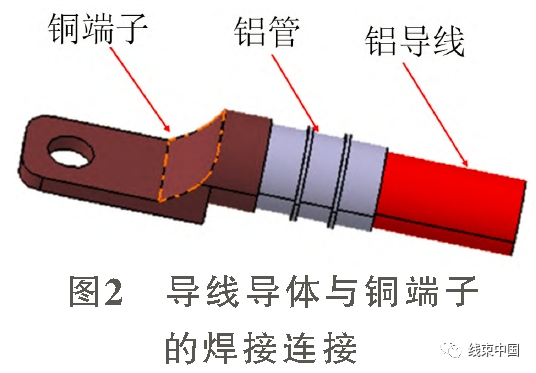

I-friction welding isebenzisa ishubhu ye-aluminium ukuze ihlinze futhi ilolonge ikhondukta ye-aluminium. Ngemva kokusika ubuso bokuphela, i-friction welding yenziwa nge-copper terminal. Uxhumano lwe-welding phakathi kwe-wire conductor kanye netheminali yethusi luqedwa ngokusebenzisa i-friction welding, njengoba kuboniswe kuMfanekiso 2.

I-friction welding ixhuma izintambo ze-aluminium. Okokuqala, ishubhu ye-aluminium ifakwe ku-conductor wentambo ye-aluminium ngokusebenzisa i-crimping. Isakhiwo se-monofilament se-conductor yenziwa ipulasitiki ngokusebenzisa i-crimping ukwakha isigaba esiphambanayo esiyindilinga. Khona-ke i-welding cross-section iyancipha ngokuphenduka ukuze kuqedelwe inqubo. Ukulungiswa kwezindawo zokushisela. Esinye isiphetho setheminali yethusi yisakhiwo sokuxhuma ugesi, kanti esinye isiphetho siyindawo yokuxhuma i-welding yetheminali yethusi. Indawo yokuxhuma i-welding yetheminali yethusi kanye nendawo yokushisela yocingo lwe-aluminium kuyashiselwa futhi kuxhunywe nge-friction welding, bese kuthi i-welding flash iyasikwa futhi ilolongelwe ukuze kuphothulwe inqubo yokuxhuma kwe-friction welding wire aluminium.

Uma kuqhathaniswa namanye amafomu okuxhumana, i-friction welding yakha ukuxhumana phakathi kwethusi ne-aluminium ngokusebenzisa i-friction welding phakathi kwamatheminali ethusi nezintambo ze-aluminium, okunciphisa ngempumelelo ukugqwala kwe-electrochemical yethusi ne-aluminium. Indawo yenguquko ye-copper-aluminium friction welding ivalwe ngeshubhu elincipha ukushisa okunamathelayo esigabeni sakamuva. Indawo yokushisela ngeke ivezwe emoyeni kanye nomswakama, iqhubeke nokunciphisa ukugqwala. Ukwengeza, indawo yokushisela yilapho i-aluminium wire conductor ixhunywe khona ngokuqondile ku-terminal yethusi ngokusebenzisa i-welding, okwandisa ngokuphumelelayo amandla okudonsa okuhlangene futhi kwenza inqubo yokucubungula ibe lula.

Kodwa-ke, ububi bukhona futhi ekuxhumekeni phakathi kwezintambo ze-aluminium kanye namatheminali ethusi-aluminium kuMfanekiso 1. Ukusetshenziswa kwe-friction welding kubakhiqizi bezintambo zezintambo kudinga imishini yokushisela ehlukile yokungqubuzana okukhethekile, enokwehlukahlukana okubi futhi okwandisa ukutshalwa kwezimali ezimpahleni ezingashintshi zabakhiqizi bezintambo zezintambo. Okwesibili, ekushiseni kwe-friction Ngesikhathi senqubo, isakhiwo se-monofilament socingo sihlanganiswa ngokuqondile ne-copper terminal, okuholela emigodini endaweni yokuxhumana ye-welding. Ukuba khona kothuli nokunye ukungcola kuzothinta izinga lokugcina le-welding, okubangela ukungazinzi kwezakhiwo zemishini kanye nogesi wokuxhuma kwe-welding.

04 Ukushisela kwe-ultrasonic

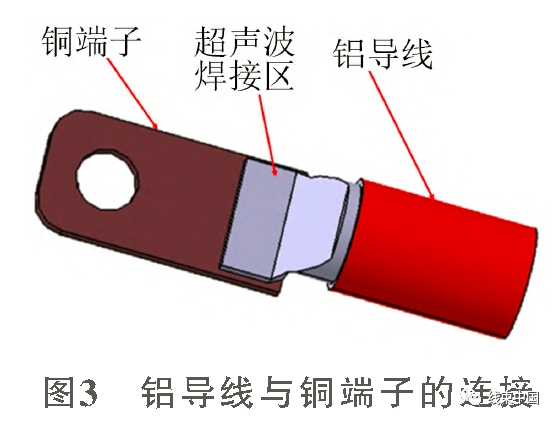

I-Ultrasonic welding yezintambo ze-aluminium isebenzisa imishini yokushisela ye-ultrasonic ukuxhuma izintambo ze-aluminium namatheminali ethusi. Ngokusebenzisa i-high-frequency oscillation yekhanda lokushisela lemishini yokushisela ye-ultrasonic, ama-monofilaments e-aluminium wire kanye nezintambo ze-aluminium namatheminali ethusi axhunywe ndawonye ukuze aqedele ucingo lwe-aluminium kanye nokuxhuma kwamatheminali ethusi kuboniswe kuMfanekiso 3.

Uxhumano lwe-welding ye-Ultrasonic yilapho izintambo ze-aluminium namatheminali ethusi zidlidliza ngamagagasi e-ultrasonic asebenza kakhulu. Ukudlidliza nokungqubuzana phakathi kwethusi ne-aluminium kuqeda ukuxhumana phakathi kwethusi ne-aluminium. Ngenxa yokuthi kokubili ithusi ne-aluminium kunesakhiwo se-crystal metal eyi-cubic egxile ebusweni, endaweni ephakeme ye-oscillation ye-oscillation Ngaphansi kwalesi simo, ukushintshwa kwe-athomu esakhiweni sekristalu yensimbi kuqediwe ukwenza ungqimba lwenguquko ye-alloy, kugwema ngokuphumelelayo ukuvela kwe-electrochemical corrosion. Ngesikhathi esifanayo, ngesikhathi senqubo ye-welding ye-ultrasonic, ungqimba lwe-oxide ebusweni be-aluminium conductor monofilament luhlutshiwe, bese uxhumano lwe-welding phakathi kwe-monofilaments luqediwe, okuthuthukisa izakhiwo zikagesi kanye nemishini yokuxhuma.

Uma kuqhathaniswa namanye amafomu okuxhumana, imishini yokushisela i-ultrasonic iyimishini yokucubungula evame ukusetshenziswa yabakhiqizi bezintambo zocingo. Ayidingi ukutshalwa kwempahla entsha engashintshi. Ngesikhathi esifanayo, ama-terminals asebenzisa ama-terminals anesitembu sethusi, futhi izindleko zokugcina ziphansi, ngakho-ke kunenzuzo engcono kakhulu yezindleko. Nokho, kubuye kube nokubi. Uma kuqhathaniswa namanye amafomu okuxhumana, i-welding ye-ultrasonic inezakhiwo ezibuthakathaka zemishini kanye nokumelana nokudlidliza okubi. Ngakho-ke, ukusetshenziswa kokuxhumeka kwe-welding ye-ultrasonic akukhuthazwa ezindaweni zokudlidliza eziphezulu.

05 Ukushisela ngePlasma

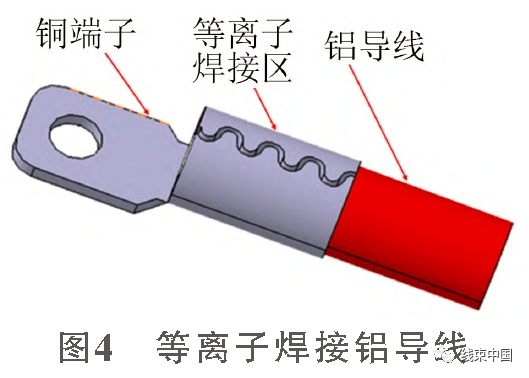

I-Plasma welding isebenzisa amatheminali ethusi nezintambo ze-aluminium ukuze kuxhunywe i-crimp, bese ngokungeza i-solder, i-arc ye-plasma isetshenziselwa ukukhanyisa nokushisa indawo ezoshiselwa, ukuncibilikisa i-solder, ukugcwalisa indawo yokushisela, nokuqedela uxhumano lwe-aluminium wire, njengoba kuboniswe kuMfanekiso 4.

Ukushisela i-Plasma yamakhondaktha e-aluminium kuqala kusebenzisa i-plasma welding yamatheminali ethusi, futhi ukucwiliswa nokuqiniswa kwamakhondatha e-aluminium kuqedwa ngokucwiliswa. Amatheminali we-plasma welding akha isakhiwo esimise okwe-barrel ngemva kokucwiliswa, bese indawo yokushisela i-terminal igcwaliswa nge-solder equkethe i-zinc, futhi isiphetho se-crimped sithi Faka i-solder equkethe i-zinc. Ngaphansi kwe-irradiation ye-plasma arc, i-solder equkethe i-zinc iyashiswa futhi iyancibilika, bese ingena emgodini wezintambo endaweni ye-crimping ngokusebenzisa isenzo se-capillary ukuqedela inqubo yokuxhuma yamatheminali ethusi nezintambo ze-aluminium.

Izintambo ze-aluminium zokushisela i-Plasma ziqedela ukuxhumana okusheshayo phakathi kwezintambo ze-aluminium namatheminali ethusi ngokusebenzisa i-crimping, ehlinzeka ngezakhiwo ezinokwethenjelwa zemishini. Ngesikhathi esifanayo, ngesikhathi se-crimping, nge-compression ratio ye-70% kuya ku-80%, ukubhujiswa nokuxebuka kwe-oxide layer ye-conductor kuqediwe, ngokuphumelelayo Thuthukisa ukusebenza kukagesi, ukunciphisa ukuphikiswa kokuxhumana kwezindawo zokuxhuma, nokuvimbela ukushisa kwamaphoyinti okuxhuma. Bese wengeza i-solder equkethe i-zinc ekupheleni kwendawo ye-crimping, futhi usebenzise i-plasma beam ukuze ukhanyise futhi ushise indawo yokushisela. I-solder equkethe i-zinc iyashiswa futhi iyancibilika, futhi i-solder igcwalisa igebe endaweni ye-crimping ngokusebenzisa isenzo se-capillary, ukuzuza amanzi okufutha usawoti endaweni ye-crimping. Ukuhlukaniswa komhwamuko kugwema ukwenzeka kokugqwala kwe-electrochemical. Ngasikhathi sinye, ngenxa yokuthi i-solder ihlukanisiwe futhi ivinjelwe, kwakhiwa indawo yokuguqula, egwema ngokuphumelelayo ukuvela kwe-creep eshisayo futhi inciphise ingozi yokwanda kokumelana nokuxhumeka ngaphansi kokushaqeka okushisayo nokubandayo. Ngokusebenzisa i-plasma welding yendawo yokuxhuma, ukusebenza kukagesi kwendawo yokuxhuma kuyathuthukiswa ngokuphumelelayo, futhi izakhiwo zemishini yendawo yokuxhuma nazo zithuthukisiwe.

Uma kuqhathaniswa namanye amafomu okuxhumana, i-plasma welding ihlukanisa amatheminali ethusi nama-aluminium conductors ngokusebenzisa isendlalelo se-welding esishintshayo kanye nongqimba oluqinile lwe-welding, kunciphisa ngokuphumelelayo ukugqwala kwe-electrochemical yethusi ne-aluminium. Futhi ungqimba lwe-welding oluqinisiwe lugoqa ubuso bokugcina bomqhubi we-aluminium ukuze amatheminali ethusi kanye ne-conductor core ngeke kuhlangane nomoya kanye nomswakama, kuqhubeke kunciphisa ukugqwala. Ukwengeza, isendlalelo se-welding esishintshayo kanye nesendlalelo se-welding esiqinisiwe silungisa ngokuqinile amatheminali ethusi kanye namajoyinti ocingo lwe-aluminium, okwandisa ngokuphumelelayo amandla okudonsa amalunga nokwenza inqubo yokucubungula ibe lula. Nokho, kubuye kube nokubi. Ukusetshenziswa kokushisela i-plasma kubakhiqizi bezintambo zezintambo kudinga okokusebenza okuhlukene okuzinikele kokushisela i-plasma, okuguquguqukayo okungefani futhi okwandisa ukutshalwa kwezimali ezimpahleni ezingashintshi zabakhiqizi bezintambo zezintambo. Okwesibili, ohlelweni lwe-welding ye-plasma, i-solder igcwaliswa ngesenzo se-capillary. Inqubo yokugcwalisa igebe endaweni ye-crimping ayilawuleki, okuholela kwikhwalithi yokugcina engazinzile endaweni yokuxhumana ye-welding ye-plasma, okuholela ekuphambukeni okukhulu ekusebenzeni kukagesi kanye nemishini.

Isikhathi sokuthumela: Feb-19-2024